Freight claim reduction, the use of a mishandling prevention device, reliable mishandled shipment evidence, measurable product return cost reduction, and a dependable rough handling tracking solution are no longer optional—they are essential for every quality assurance team that wants to protect profits and brand reputation.

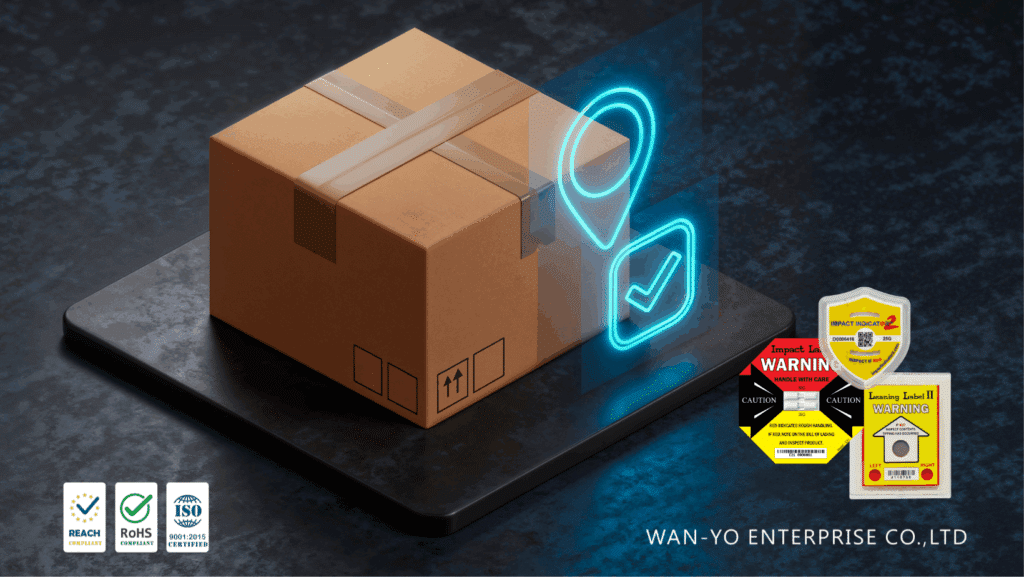

Whether you’re shipping precision electronics, delicate medical devices, or high-value machinery, your Quality Assurance role isn’t just about testing products before they leave the factory—it’s about ensuring they arrive exactly as they left, no matter what happens in transit. That’s where Shock Indicators, Impact Indicator 2, Tilt Indicators, and Pallet Cushions step in as your frontline allies.

![]()

Freight Claim Reduction – The QA Department’s Hidden KPI

For QA professionals, freight claim reduction is more than a financial target—it’s a sign that your preventive measures are working. Every claim avoided means fewer customer disputes, less paperwork, and a stronger trust bond with clients.

By integrating Shock Indicators into your outbound shipments, you create a visible deterrent for rough handling. Handlers know they’re being monitored, which drastically reduces the chance of excessive drops, vibrations, or impact damage. Combined with Pallet Cushions to absorb shocks at the base level, you’re not only preventing damage but also building a solid case for claim defense if incidents occur.

Mishandling Prevention Device – Your QA “Invisible Supervisor”

A mishandling prevention device like a Tilt Indicator or Shock Indicator acts as an ever-present supervisor during transit. Unlike humans, these devices don’t blink, get distracted, or forget to log an incident. They silently watch over each shipment, ready to reveal whether it was tipped, dropped, or jolted beyond safe limits.

For QA teams, this means no more “it must have happened at the warehouse” debates—just clear, indisputable evidence of when and how mishandling occurred.

Mishandled Shipment Evidence – Turning QA into the Judge and Jury

When freight damage happens, arguments follow. Without proof, it becomes a frustrating back-and-forth between shipper, carrier, and customer. Mishandled shipment evidence from indicators puts QA in control.

Shock Indicators change color if a package experiences impact above a set threshold, while Tilt Indicators record directional tipping events. When paired with Pallet Cushions, you create a complete story—where the package was hit, how it was tilted, and whether the cushioning performed as intended. This evidence not only resolves disputes quickly but also strengthens your position in freight claims.

Product Return Cost Reduction – A Direct Win for QA Budgets

Every returned product drains QA’s budget—not only in inspection and rework costs but also in brand trust. Using these preventive tools reduces the likelihood of damage before it happens. This directly translates to measurable product return cost reduction.

Imagine cutting your return rate by even 20%. That’s fewer customer complaints, faster resolutions, and more resources freed up for product improvement instead of post-mortem damage investigations.

Rough Handling Tracking Solution – Seeing What QA Couldn’t See Before

A rough handling tracking solution is essentially a new set of eyes for QA. Shock Indicators pinpoint excessive G-force events, Tilt Indicators reveal improper orientation, and Pallet Cushions mitigate vibration and vertical shock before it reaches your products.

By logging and analyzing these events, QA can identify patterns—like a specific route, facility, or carrier consistently mishandling shipments—and take targeted corrective action.

![]()

From freight claim reduction to rough handling tracking solutions, every mishandling prevention device we provide turns mishandled shipment evidence into real product return cost reduction

For QA teams, the days of guessing are over. With a well-implemented system that includes Shock Indicators, Tilt Indicators, and Pallet Cushions, you gain the power to:

-

Reduce freight claims before they even happen

-

Deter mishandling with visible monitoring

-

Gather undeniable shipment evidence

-

Slash product return costs

-

Track and eliminate rough handling at its source

This is not just a shipping upgrade—it’s a QA revolution.

Protect your shipments, protect your brand.

Contact us today to build your custom QA-focused freight claim reduction plan with our full range of mishandling prevention devices, mishandled shipment evidence tools, and rough handling tracking solutions.