- Preface

- CHAPTER 1: What is Shock Indicator?

- CHAPTER 2: How Do Shock Indicators Work?【Reveal Industry Secret】

- CHAPTER 3: How Can Shipping Impact Indicators Help?

- CHAPTER 4: How To Select Shock Indicators for Shipping?

- CHAPTER 5: How To Correctly Use Shock Indicator Labels?

- CHAPTER 6: Shock Indicators Prices and Functions

- Summary

Preface

Why shock indicators can protect the goods? It looks like just a sticker. – Wonder why? You can jump directly to #What benefits Shock Indicator Bring?

70% of you, to this article, are because your customers ask to stick shock indicators to protect the goods they ordered. The rest of 30% has serious problems with goods damaged as delivery and you don’t know how to reduce cargo damage and clarify responsibilities.

The following contents are going to take you to comprehend all the secrets of the industry.

.What is shock indicator?

.What is the “G” of a g shock indicator?

.How do shock indicators work?

.When to use g shock indicator?

.How to select shock indicators for shipping?

.How to correctly use shock indicator label?

.Where to buy impact indicators?

.How much is the price?

Shock indicator is also known as: impact indicator, shock sticker, shock indicator labels, impact monitor, shock indicator sticker, shipping impact indicators, impact indicator stickers, shipping shock indicators, etc…

CHAPTER 1: What is Shock Indicator?

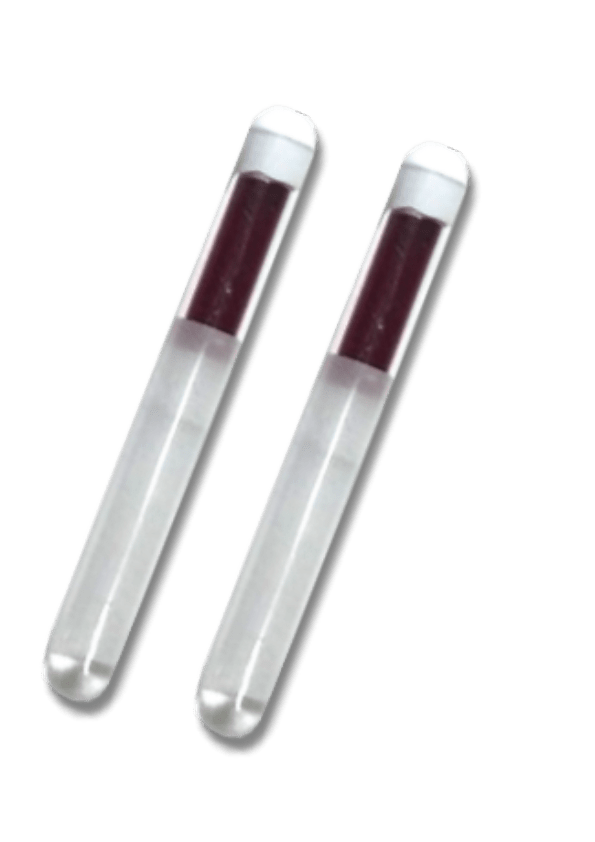

Activation View of Shock Indicator 50G

As the name implies, the shock indicator is a product that can indicate the shock force through the display window. Shock force is known as impact force or acceleration(G).

The shock indicator can record the vibration intensity during transportation or goods exposed to inappropriate environmental conditions, which is liable to the relevant responsible person. Mostly, indicators are used in the transportation or storage of goods. With different degrees of impact resistance for each package, you should select different models for different goods. (Please refer to #How to Choose a Shock Indicator?)

There are 5 common product models: 100G, 75G, 50G, 37G, 25G, in order from least sensitive to most sensitive. Generally, the colors of commercially available shock indicators follow the industry’s specifications. They are all eye-catching colors to attract the attention of couriers and handlers.

| 100G | 75G | 50G | 37G | 25G |

| Green | Orange | Red | Purple | Yellow |

Shock Indicator – Sensitivities to Models

1-1 What Is the “G” of Shock Indicator?

Each shock indicator has a corresponding “G”, but what it mean? You probably associate “G” with the gram of weight due to package weight. However, the “G” stands for acceleration G.

“Acceleration G” is the G-force we hear when we play roller coasters in amusement parks or pilots often hear the human body under fast flight. The acceleration of an object under the action of gravity, also known as gravitational acceleration, usually uses “g” to represent.

To put it simply, shock indicator 50G means that it takes 50 times the acceleration g-force to activate the product and start the color change.

Read More

|

What Is『G』 Of Shock Indicator? Each shock indicator has a corresponding “G”, which means that when the indicator is subjected to a shock acceleration that exceeds the G value number… |

1-2 Structure of Shock Indicator

Have you noticed informative content on the label? What are these contents for?

.Sticker + Plastic Housing + G-Sensor

The shock indicator is a simple and inexpensive device, made of 3 parts – “sticker“, “plastic housing“, and “G-Sensor“. G-Sensor is placed in the plastic housing to protect the detection device.

.Content

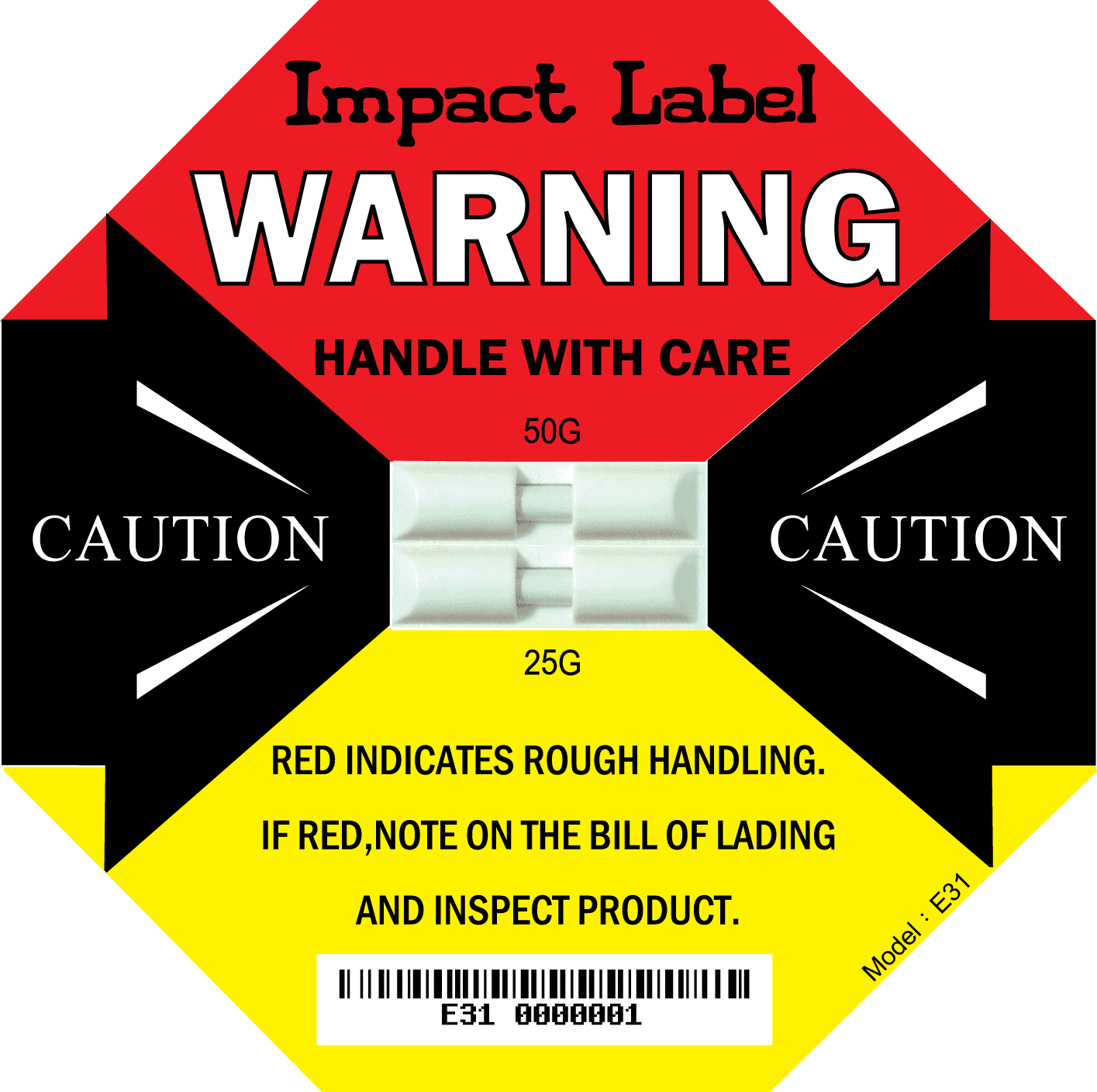

The information contains the brand name, warning slogan, and serial number on the sticker. The warning slogans include words such as “Handle With Care” and “Caution” to remind handlers to pay attention to this package. The serial number is to prevent the possibility of tamper. Handlers may replace the shock indicator with a new one if activated.

Explosion Diagram of Shock Indicator

1-3 Companion Label

To remind handlers of shock indicator(s) applied to the cargo, a shock indicator usually with a warning label & a small warning sticker. They separately apply to cargo and bill of lading.

.Warning Label(Length X Width:197 x 134 mm) |

Functions & Notes:

a. Drawing the Attention of a delivery man b. Clearly indicate the Processing Steps for activated the label (Turn Red) |

|

|

Functions & Notes:

a. Please stick the small warning sticker on Bill of Lading. |

CHAPTER 2: How Do Shock Indicators Work?【Reveal Industry Secret】

The product technology of shock stickers is slightly different in each manufacturer, and it has always been the secret, however, in fact, the working principle is basically divided into physical change and structural change.

2-1 Physical Change

Imagine the water droplets on the ceiling fall after you slap the ceiling. The droplet is the red ink and the slap is the force of impact. While the viscosity of the water drop gets higher, the required impact force is greater to make it fall. This is the design principle of different “G” shock indicators.

When the indicator is stable, the red ink remains in the transparent impact tube due to its viscosity and surface tension. Then an external force impacts the tube, the red ink flows out, and the coating in the transparent tube absorbs and spreads rapidly throughout the entire transparent tube. Its working principle is similar to toilet paper in absorbing liquid, commonly known as capillarity. People can see that the shock indicators are activated in red.

How Do Shock Indicator Work?

2-2 Structural Change

The structural change requires an elastic material to fix it. When an external force intervenes, the fixed material will loosen; and the degree of this elastic force is the design principle of different g shock indicators.

|

|

2-3 Impact Label

Impact Label is a brand of WAN-YO Enterprise Co., Ltd, 100% made in Taiwan. It currently has a global market share of about 35%. The most famous products are Impact Label and the world’s first Dual Impact Label, both use physical change design to detect impacts.

| Impact Label: Physical Changes, 360º Impact Detection |

|

|

| Dual Impact Label: Physical Changes, 2 Impact Points Detection |

|

|

|---|

| Impact Tube: Physical Changes, Smallest G-Sensor |

|

CHAPTER 3: How Can Shipping Impact Indicators Help?

The shipping impact indicator can indicate the “impact force” and impact monitor, but how exactly do they help?

3-1 What is the Issue?

The shipping impact indicator is your best choice for the following issues.

- Damaged goods as arrived in customer’s hand causes bad reputation.

- Don’t know where the goods are damaged.

- Shipping company shrinks responsibility and makes excuses for damaged delivery.

- Insurance claims hardly settle down.

3-2 What are the Benefits of Shipping Impact Indicators?

.Reduce Cargo Damage Rate by 70% or more:

The handlers are “extremely careful” when your goods are affixed with the indicator because the shock indicator can record the impact as an impact or a shock occurs.

.Promote Corporate Image:

Customers know that you treat their goods more responsibly than other suppliers when they receive the goods with indicators.

. Find Out the Damage Reason:

The indicator can clearly distinguish whether the goods encountered an abnormal impact, shock, or fall in the factory or during transportation.

. Penny and Pound Wise:

It only takes a little cost to have better protection for your expensive goods. Once the goods are damaged, the amount of loss is terribly high.

. Strong Evidence:

The irreversible color-change mechanism can be used as strong evidence.

CHAPTER 4: How To Select Shock Indicators for Shipping?

Each customer has a different package, protection, weight, and product impact resistance, so we provide the following 4 methods for you to choose from.

Method 1. Selection Guide Table ——————————- The Fastest ; Least Accurate

Method 2. Activation Height Table to Test Reports ———- Faster ; More Accurate

Method 3. Do a Drop Test ————————————— Most Accurate

Method 4. Collect Data after Shipping Out ——————– For Untestable Goods

To shorten the article, please refer to 3 Mins》4 Ways, Select Shock Indicator Sticker for more details.

CHAPTER 5: How To Correctly Use Shock Indicator Labels?

The shock indicator label is a precise impact monitor device. Only the correct use of the product can accurately detect the exact G force. Don’t miss out, and check the 3 parts carefully.

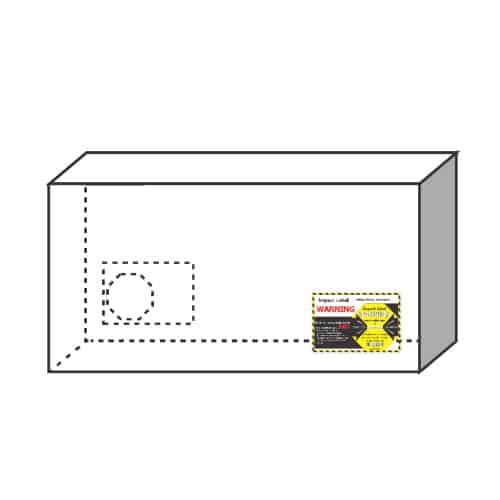

5-1 Steps for Usage

- Apply the warning label in the correct position on the package.

- Tear off the shock indicator label and apply it to the yellow area of the warning label.

- Stick a small warning sticker on the bill of lading as a reminder to handlers of the shock indicator label.

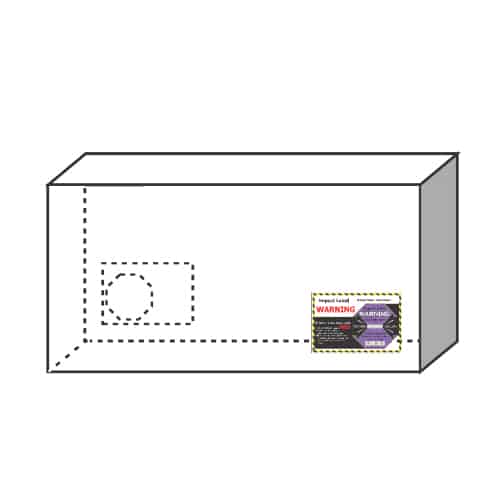

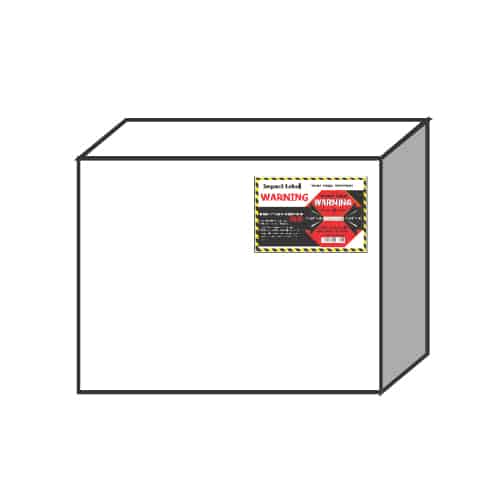

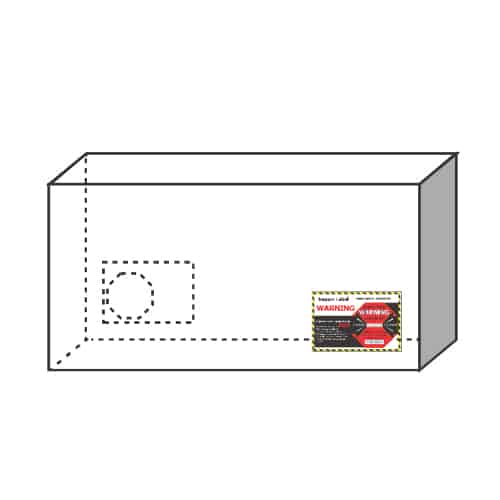

5-2 Applied Placement

The applied position is a crucial part of the shock indicator label, and the correctness of the applied position also affects the sensitivity of the indicator to detect impact and shock.

Recommendations for the Placement of Product Models:

| Shock Indicator 25G |

Bottom Corner for Large Goods |

|

| Shock Indicator 37G |

|

|

| Shock Indicator 50G |

|

|

| Shock Indicator 75G |

|

|

| Shock Indicator 100G |

Top Corner for Small Goods |

|

5-3 Precautions!

You need to apply the indicator on the placement of packaging where the product is more susceptible to impact. Always remember to “Apply on a hard surface“, do not apply to the center of the carton or the stretch film.

|

|

| Apply it on Cartons (Ture) | Apply it on Packaging Film (False) |

|

|

| Apply it on the corner (True) | Apply it on the center (False) |

5-4 Shock Indicator Label Activation, What to do?

The color-change of the shock indicator can immediately reflect the impact of the goods, but it cannot guarantee that the goods will be damaged as a result; therefore, when the indicator activation, the receiver “Do Not Return“, “Take Photos and Inspect” of the package, and “Note On The Receipt“.

Should you require to reject goods directly, we strongly recommend using the Dual Shock Indicator.

Dual Shock Indicator by WAN-YO

Read More

|

What’s Next for Activation? How To Maximize Utility? Do you know the correct procedure for shock and tilt indicator activation? You’re likely at risk of subsequent disputes if any wrong action. On the contrary, the right action leads to clarified responsibility, acquired compensation, and improved shipping |

CHAPTER 6: Shock Indicators Prices and Functions

There are many brands of shock indicators on the market, what is the difference? What are the reviews?

6-1 【Transparent Market Price】Impact Label

Impact Labels are sold in various countries via agents or distributors. You can get a glimpse of the price list of shock indicators on the market through the table below.

From the price list, we can know that the prices of other brands are the most favorable, but most minor brands have many problems in the accuracy of the G value and quality control, which probably causes great troubles afterward. If the price difference is not significant for you, don’t make fun of your company’s products and reputation.

| Company Name | Product Name | Price (USD) |

| WAN-YO | Impact Label | $ XX – $ XX |

| Dual Impact Label | $ XX – $ XX | |

| Impact Tube | $ XX – $XX |

Shock Indicator Market Price

6-2 Where To Buy Shock Indicators?

The marketing strategies of the 3 major brands are all sold as regional agents, so purchasing from the local agents or distributors is the best way.

Benefits of Buying From Agents/Distributors

- Support Small Amount

Local distributors and agents can support small orders so that consumers do not have to buy a large number of products at one time and avoid risks.

- Trade and Fast

Agents and distributors all have basic stocks, no need to communicate with trade terms based on Intercoms 2010 and transportation risks, and can quickly supply products nearby, making it easier for consumers to buy.

- Local Language

Local agents and distributors are familiar with local terms and cultures which can communicate with customers more quickly and clearly and provide various assistance, such as customer complaints and technical guidance.

- Safe Bank Transactions

Safer and faster transactions in the area eliminate the hassle of international payments.

- After-Sales Service

After receiving the product or using the product, the local distribution agent can respond and support more quickly if there is any problem. No need to wait for a long time and a long communication process due to time differences.

Summary

In the preface, we mentioned that the shock indicator label looks like a sticker, why can it protect the goods? The information we have compiled above is believed to be enough to give you a more comprehensive understanding of the shock indicator.

If you encounter a problem with the delivery of goods, “No Doubt!” At present, the shock indicator is cheap and easy to use. It does not need to change the product design or waste resources to solve the delivery problem – becomes “Penny Wise, Pound Wise.”

You can also find the industry you’re from through our “Industry Application” and view our recommended applicable product information.

Have Questions About Shock Indicators?

| TECHNICAL SUPPORT | CONTACT US |

Read More

|

【Are Damaged Goods Impacting Your Service?】 It may not come as a surprise that most Exporter’s number one pain is damaged goods, even after paying top dollar to reduce damages. |

|

【6 Secrets】About Tilt Indicators Price, How To Reset? How It Works? 2021 Updated! Cargo insurance can help to cover up the loss of product, however, it cannot help to get and solve the root of the problem. Customers always place complaints about your products or components in all mess upon parcel/shipment arrival and even ask for returns of goods or refunds… |

#Shock Indicator #Impact Indicator #Shock Sticker #ShockIndicator Labels #Impact Monitor

這篇內容同時也提供 [繁體中文] 版。

Bottom Corner for Large Goods

Bottom Corner for Large Goods

Bottom Corner for Large Goods

Bottom Corner for Large Goods Top Corner for Small Goods

Top Corner for Small Goods