Most medical equipment is precision instruments, which contain fragile glass or precision parts, such as MRI machines and CT scan machines.

During transport or in storage, damage, malfunctions or inaccuracies may occur due to vibration, impact, or bumpy roads, etc., even if it appears to be minor damage, resulting in delayed patient treatment, increased maintenance costs, and damage to the manufacturer’s reputation.

Perfect packaging protection as well as monitoring entire product transportation process for medical products are crucial to medical device manufacturer.

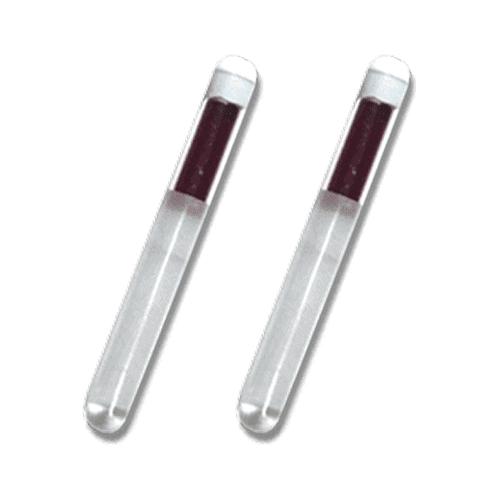

Place an Impact Label (shock indicator) in the outer packaging or insert an Impact Tube inside the product to monitor drops, shakes and vibrations while Leaning Label (tilt indicator) series help you to monitor tilt and overturn, which is a double guarantee for product quality.

※ Medical equipment transportation process and precautions

1. Check the condition of the vehicle before leaving the vehicle and check whether there are any obstacles on the route

2. Carefully check whether the goods are intact and whether the number and number of equipment are consistent with the bill of lading

3. Check the outer package, the impact indicator and tilt indicator if is complete

4. Check the binding secure after loading to avoid collision and dumping during transportation

5. When the device arrives at the destination, check whether the impact indicator and tilt indicator are activated and take pictures.

Read More

|

【2021】Secure Medical Equipment Transportation Medical equipment is essential for patient care, but sometimes it can seem like such a hassle to transport it without sustaining damage. The equipment is often highly sensitive and fragile, not to mention expensive. |

|

Why 66% Of Medical Equipment Arrived Damaged? $1,000,000 Loss! In 2018, a prominent medical equipment manufacturer finished orders for 12 X-ray machines and cheerfully shipped them to clients. Customers were dissatisfied with them. |

這篇內容同時也提供 [繁體中文] 版。