The technology of automobile-related products has been greatly improved. Products are accompanied by multiple costly electronic parts. Costly great loss comes behind once any components are damaged. Production may stop or product may be defective until the cause is identified and the risk is analyzed.

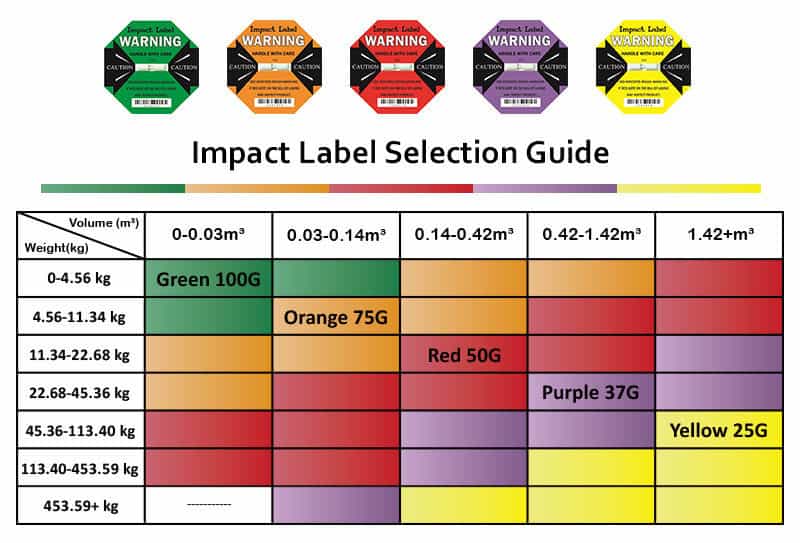

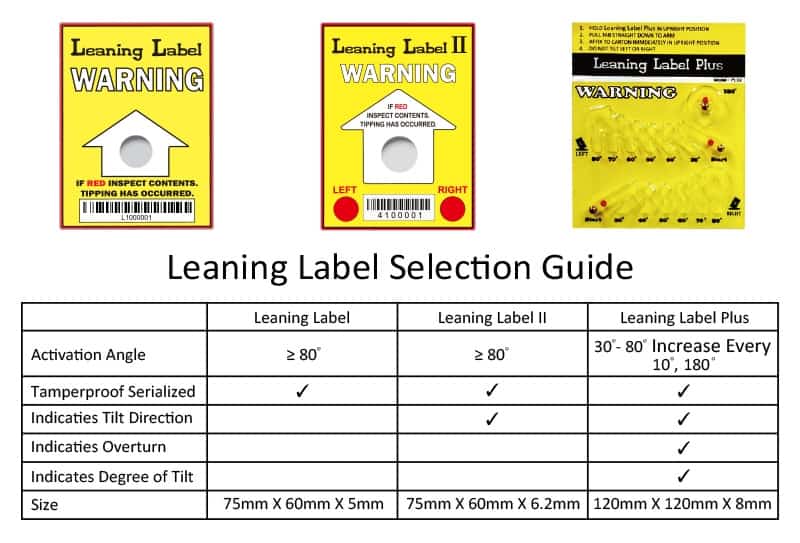

The Impact Label (shock indicator) and Leaning Label (tilt indicator) can monitor the storage or transportation of goods for 24 hours, and can easily determine whether the goods are being treated abnormally through a simple and cost-efficient device.

The world-renowned major manufacturers have been applied Impact Label and Leaning Label for a long time. Don’t you help your company solve transportation problems right now?

※ Common transportation methods for auto and truck parts

SKD (Semi-Knocked Down)

CKD (Copletely Knocked Down)

※ Common transportation issues for auto and truck parts

1. Corrosion: most occur in sea freight

2. Damage: most occur by human damage during sea and air freight.

3. Scratch: Incomplete packaging protection

這篇內容同時也提供 [繁體中文] 版。