- Freight Logistics Management Today: High Volume, Low Visibility, High Risk

- Freight Logistics Management Pain Point: Damage Happens, but Accountability Is Missing

- How Handling Damage Indicators Improve Freight Logistics Management Control

- Why Manufacturers Should Lead Freight Logistics Management Improvements

- Freight Logistics Management Is a Strategic Advantage

- Partner with Wan-Yo to Strengthen Your Freight Logistics Management

Freight logistics management is one of the most critical responsibilities inside a manufacturing organization.

For professionals who plan internal transportation, manage outbound shipments, or control logistics performance, one reality is unavoidable: even a small handling mistake during transportation can turn into major financial loss.

In today’s global supply chains, freight logistics management is no longer only about cost and delivery time. It is directly connected to logistics damage prevention, asset control logistics, and long-term logistics risk control.

This article is written for logistics managers, supply chain managers, and operations leaders who are under pressure to reduce transport damage, protect assets, and maintain customer trust — without slowing down operations.

Freight Logistics Management Today: High Volume, Low Visibility, High Risk

In modern manufacturing environments, freight logistics management involves complex flows. Products move through factories, warehouses, freight forwarders, ports, and last-mile delivery partners. Each transfer point introduces new risks, yet visibility often becomes weaker as shipments move further away from the factory.

From an internal perspective, many logistics teams face the same challenges. Damage is reported by customers, but the exact point of failure is unclear. Carriers deny responsibility, warehouses blame transportation, and internal teams lack objective data. As a result, logistics risk control becomes reactive instead of preventive.

This situation creates a serious gap in asset control logistics, where companies technically own the goods but lack real control once they leave the facility.

Freight Logistics Management Pain Point: Damage Happens, but Accountability Is Missing

One of the most common problems in freight logistics management is not the damage itself — it is the inability to prove when and how the damage occurred.

Without clear evidence:

-

Claims take months to resolve

-

Customer relationships become strained

-

Logistics costs quietly increase

-

Internal trust between departments erodes

This is why handling damage indicators are becoming a standard tool in logistics damage prevention strategies. They provide visual, objective signals that support logistics risk control across the entire transportation process.

How Handling Damage Indicators Improve Freight Logistics Management Control

Handling damage indicators act as a simple but powerful extension of freight logistics management. Once attached to a shipment, they monitor handling conditions continuously, without requiring power, software, or training.

For logistics teams, this creates three immediate benefits.

- First, damage prevention improves because handlers know shipments are monitored.

- Second, asset control logistics becomes measurable, not assumed.

- Third, logistics risk control shifts from guesswork to evidence-based decisions.

From a management perspective, this means fewer disputes, faster corrective actions, and more predictable logistics performance.

Shock Indicators for Logistics Damage Prevention

Shock indicators are designed to detect excessive impact during transportation. In freight logistics management, they are particularly effective for products that are sensitive to drops, collisions, or rough handling.

When a shock indicator is triggered, it provides immediate visual confirmation that improper handling occurred. This clarity supports logistics damage prevention by discouraging careless handling and reinforcing standard operating procedures across logistics partners.

As a manufacturing factory, Wan-Yo designs shock indicators specifically for industrial freight logistics management, ensuring stable performance across long-distance and multi-modal transportation.

Tilt Indicators for Asset Control Logistics

In many industries, orientation matters as much as impact. Products that must remain upright during transport face high risk if tilted during loading, stacking, or forklift movement.

Tilt indicators play a critical role in asset control logistics by clearly showing whether a shipment exceeded safe tilt angles. For freight logistics management teams, this reduces internal handling errors and strengthens compliance across warehouses and carriers.

Tilt indicators are widely applied in machinery, liquid products, and fragile assemblies where logistics risk control depends on maintaining correct orientation at all times.

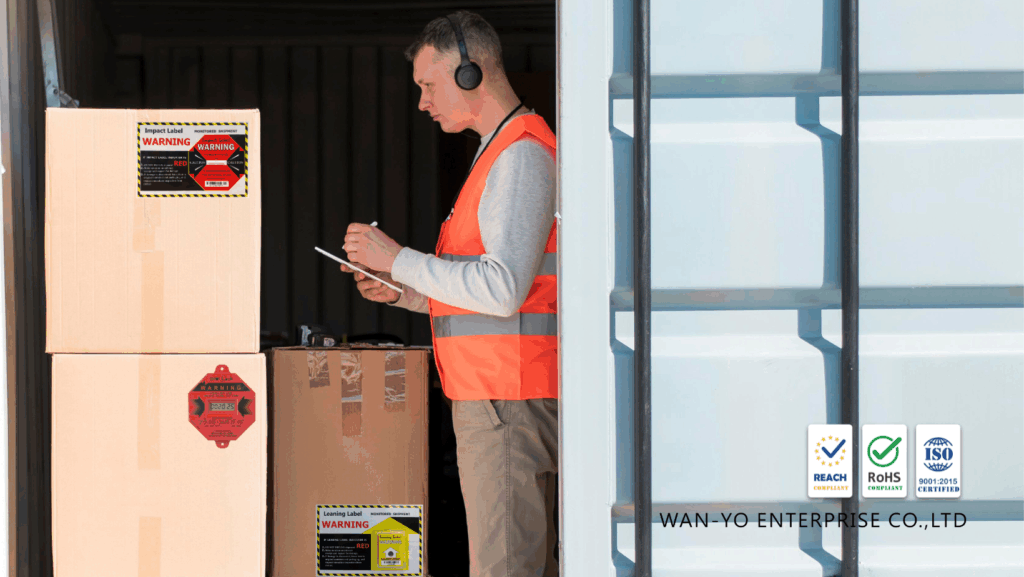

Impact Indicator 2 for Logistics Risk Control

For organizations seeking a higher level of logistics risk control, Impact Indicator 2 provides enhanced monitoring capability within freight logistics management frameworks.

Impact Indicator 2 is engineered to respond only to damaging impact levels, reducing false triggers while maintaining clear visibility. This makes it suitable for standardized deployment across large shipment volumes.

By integrating Impact Indicator 2 into freight logistics management processes, companies gain consistent, interpretable data that supports carrier evaluation, claim handling, and continuous improvement initiatives.

Pallet Cushion Solutions for Damage Prevention

Not all logistics damage comes from obvious drops or impacts. Continuous vibration, stacking pressure, and repeated micro-shocks can cause hidden damage that only appears after delivery.

Pallet cushion solutions address this risk by absorbing shock and distributing load during transportation and storage. Within freight logistics management systems, pallet cushions enhance logistics damage prevention by protecting products at the pallet level.

This approach is especially valuable for high-value goods, export shipments, and long-haul transportation routes.

SHOCLock for Asset Control Logistics

Shoclock indicators offer an advanced layer of insight by recording both the severity and direction of impacts. For freight logistics management professionals, this data strengthens asset control logistics by revealing handling patterns rather than isolated incidents.

With Shoclock, logistics risk control becomes analytical instead of reactive. Companies can identify high-risk routes, problematic handling points, and recurring operational weaknesses.

Why Manufacturers Should Lead Freight Logistics Management Improvements

Many companies rely on carriers to manage risk, but effective freight logistics management must start at the manufacturing level.

As a manufacturer, WAN-YO understands the operational reality behind logistics damage prevention. We design and produce handling damage indicators that align with real-world manufacturing workflows, packaging systems, and logistics constraints.

Our product portfolio — including shock indicators, tilt indicators, Impact Indicator 2, pallet cushion solutions, and Shoclock — supports scalable, manufacturer-led logistics risk control.

Freight Logistics Management Is a Strategic Advantage

When freight logistics management is executed with proper damage prevention and asset control logistics tools, the results extend beyond cost reduction.

Companies experience:

-

Lower damage rates

-

Faster claims resolution

-

Stronger customer confidence

-

More predictable logistics performance

In competitive global markets, this level of logistics risk control becomes a strategic advantage, not just an operational improvement.

Partner with Wan-Yo to Strengthen Your Freight Logistics Management

If you are responsible for freight logistics management and want to reduce damage, improve asset control logistics, and implement effective logistics damage prevention, WAN-YO is ready to support you as a manufacturing partner.

We do not simply sell indicators. We help manufacturers design logistics risk control systems that work in real operations.

Take Control of Your Freight Logistics Management

Contact Wan-Yo today to discuss your freight logistics management challenges.

Request product information, samples, or a technical consultation with our team.

“Upgrade Your Freight Logistics Management with WAN-YO’s Monitoring Solution”

| Monitoring Series |