Do you know that the “Apply Placement” directly affects the accuracy of shock indicator label?

” Is the shock indicator label just a sticker for decoration?” from customers’ complaints.

The goods are seriously damaged, but the Impact Label is not activation. After tests and investigation, we realized that 2 main reasons cause this problem.

1. Wrong Models

We have an article to explain how to select shock indicator labels. Please refer to 『4 Ways』 To Choose Shock Indicator Models.

2. Wrong Placement

Please read the following contents. We will explain it in detail.

Why does Wrong Placement Affect the Accuracy of Shock Indicator Label?

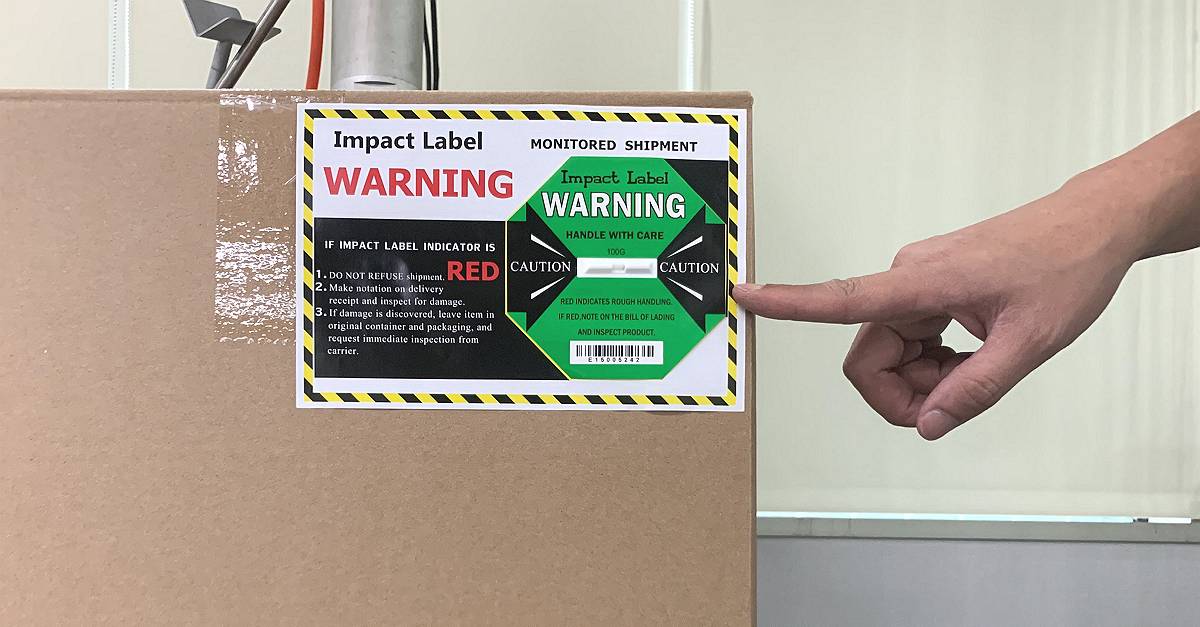

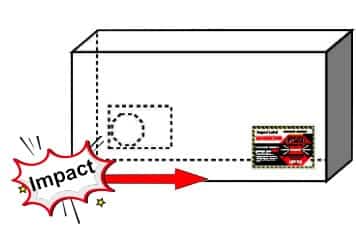

The shock indicator label is a sensor that color change occurs when the sensor receives the acceleration. In other words, if you apply the shock indicator label on the placement where hardly receive any impact force, therefore, the indicator inactivate and is ineffective.

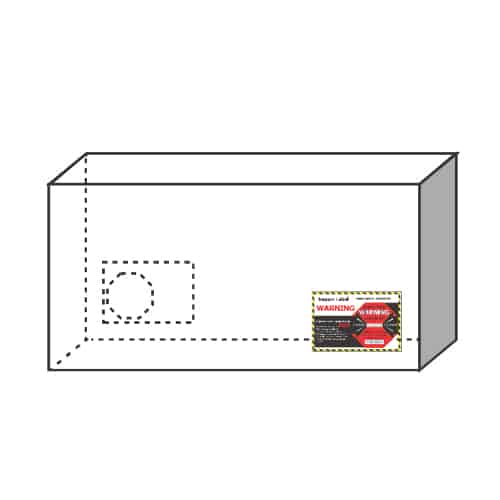

|

When an impact occurs, the shock indicator label will never activate by the impact force delivered from the carton under the stretch wrap is not completely applied on the carton.

As a result, applying shock indicator labels should place it near the corners of the package, which is the most fragile part.

※ Do not place the shock indicator label at the center of the package because the center is the softest part of the packaging.

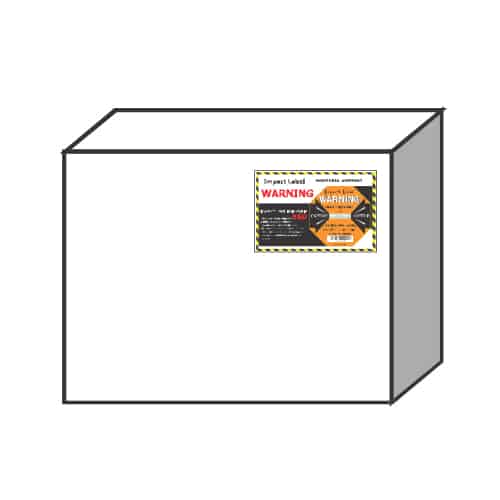

So, How Do We Apply Shock Indicator Label?

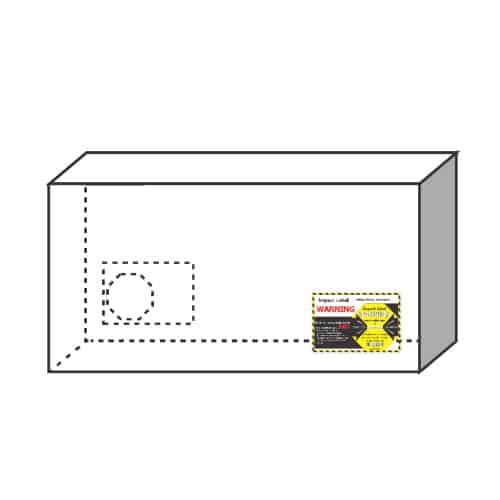

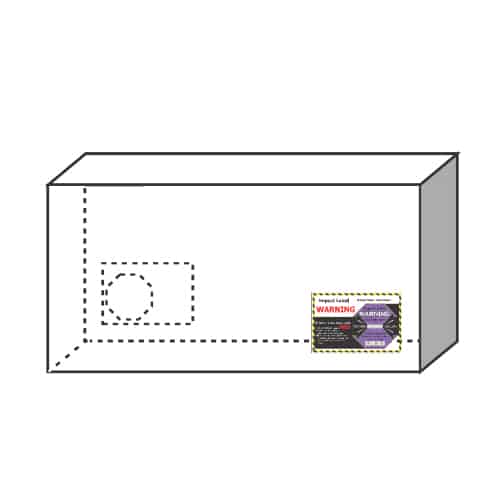

According to the table below, you will find out that the placement of shock indicator labels is according to “Size and Weight” to apply at the corner. The bigger and heavier goods are, the near corners we apply on. The reason is that the impact occurs at the bottom for large goods. Therefore, we recommend applying it on the bottom corner.

Big Goods : The goods coudldn’t be carried by a person. (can be carried by machine)

Small Goods: The goods can be carried by a person.

Recommendations for the Placement of Product Models:

| Shock Indicator 25G |

Suggestion: Shock Indicator 25G |

|

| Shock Indicator 37G |

Suggestion: Shock Indicator 37G |

|

| Shock Indicator 50G |

Suggestion: Shock Indicator 50G |

Suggestion: Shock Indicator 50G |

| Shock Indicator 75G |

Suggestion: Shock Indicator 75G |

|

| Shock Indicator 100G |

Suggestion: Shock Indicator 100G |

|

Why Should Large Cargo Apply 2 Pieces of Shock Labels?

The volume of large cargo is big and the impacted point is random. The distance between the impact point and indicator is probably far from each other. If we apply only 1 shock label on the large cargo, the indicator might not activate because of a decrease impact force during transmission.

Therefore, we recommend applying at least two shock indicator labels on the opposite corners to reduce the inability of detection.

Force Transmission – Big Cargo

For small goods, the upper right is the recommended placement because the label is more obvious on the top for small size cargo.

On the other hand, the small goods are easy to overturn or flip because small goods are easy to carry. The handling in height is over 90cm in general. As a result, it is unnecessary to apply on top or bottom.

Summary

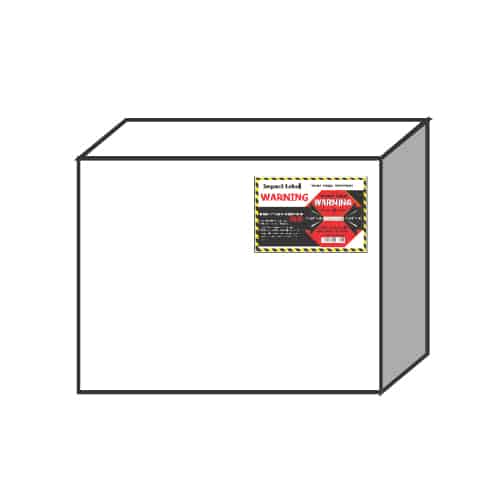

Now, you understand the placement is crucial to shock labels. Just keep in mind the principle, then the functions of shock indicator labels are fully operated. However, you better effectively communicate with handlers to effectively utilize the functionality of the shipping damage indicator. We recommend reading the following info or contact us directly before using it.

Read More

|

Shock Indicator Activation, What’s Next? How To Maximize Utility? You’re likely at risk of subsequent disputes if any wrong action. On the contrary, the right action leads to clarified responsibility, acquired compensation, and improved shipping quality, which realizes reduce cargo damage by 70%… |

這篇內容同時也提供 [繁體中文] 版。