Hundreds of thousands of companies all over the world have been partnering with Wan-Yo for decades. See how one of them met us.

Industry: Solar Industry

Solution from Wan-Yo: g-force indicator label

Challenge for the Solar Industry

Shipping solar modules could be very expensive for a lot of reasons. The following are key contributing factors.

1. We need to protect solar modules in shipping to minimize the chances that they will be damaged and the glass will shatter in transit. Therefore, shipping solar modules requires wooden pallets that could better pack and cover them.

What’s more, because they can’t be stacked, when loaded on the truck, these solar modules take up a full column of room on the truck. The packaging of solar modules could be so extensive that the shipping costs rates have soared.

2. Another reason resulting in the high shipping costs is the shipping damage. The most dismaying situation is when our manufacturer receives the shipment and finds the solar module is cracked, scratched, containing microcracks, or even broken because of shipping hazards.

For us, the solar industry, shipping damage could happen anywhere and anytime. It’s much more likely that shipping damage occurs when the item is loaded, transported, and unloaded. Most of the time, we find handlers don’t handle the packaging with care, then it will take more time, effort and money for us to deal with the damage.

Since creating solar modules could take us great efforts, once the shipping damage occurs, the loss would be considerable. Damage to solar modules during transportation could cause harmful consequences as the following.

(1) Some microcracks are not always visible to the eye. However, even the microcracks could adversely affect the operation system in the future.

(2) It could affect longevity of the system, as well as the efficiency it can operate.

(3) It would lower energy output, and cost extra energy.

Solution for the Solar Module Microcracks Shipping Damage

Since the shipping damage leads to considerable loss for the solar industry, our priority for them is to lower the damage rate. Hence, the best solution for us is Wan-Yo’s g-force indicator label. Impact indicator labels help us solve the problems in two crucial ways.

(1) Spot the issue

With Wan-yo’s impact indicators, our receivers don’t need to open the box to identify damaged goods. What’s better, the manufacturers don’t need to worry that the microcracks will have a negative impact on the operation system in the future. Because the g-force indicator label could effectively tell us when and where the boxes were mishandled. Tracking down the trouble spots is even easier so that we could effectively and efficiently assign accountability for our supply chain.

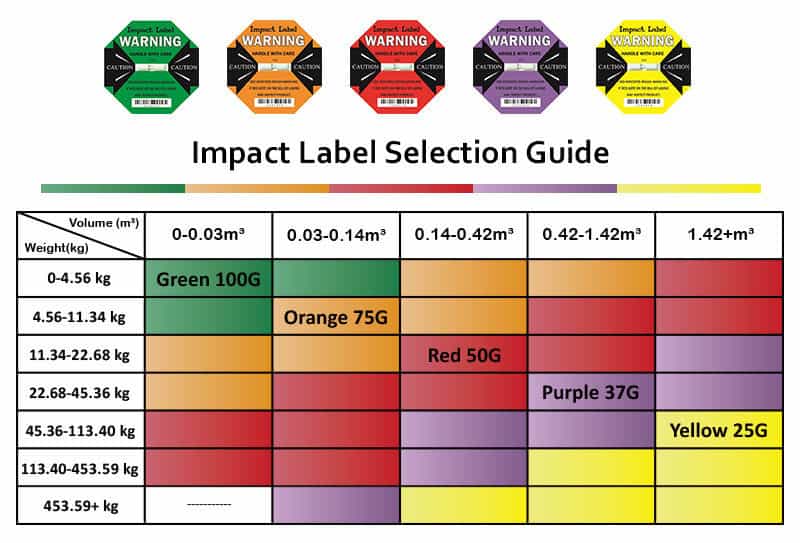

【Activation Height – Impact Label】| WAN-YO

(2) Prevent mishandling

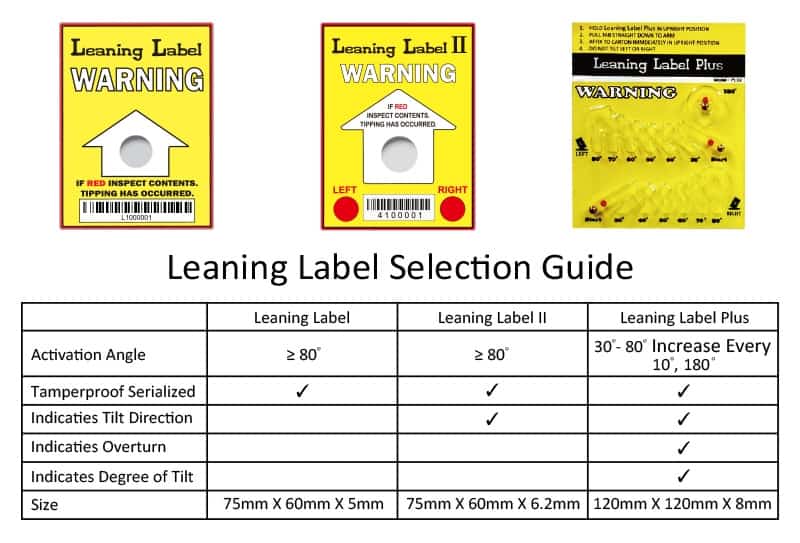

With the g-force indicator label affixed to all the packaging, handlers know they must take extra caution when handling our cargo. The device is tamperproof, which means once it’s activated, no one could reset it or pretend impact never occurred. The impact indicator is not only a reminder for receivers, but for handlers.

Benefits of Applying G-force Indicator Labels

After using g-force indicator labels for the shipment of solar modules, we noticed the damage rate has decreased over the weeks, which makes us able to manage to drive down the costs resulting from damage. Since we could track down trouble spots with the indicator, we started improving the supply chain processes and the outcomes as well.

這篇內容同時也提供 [繁體中文] 版。