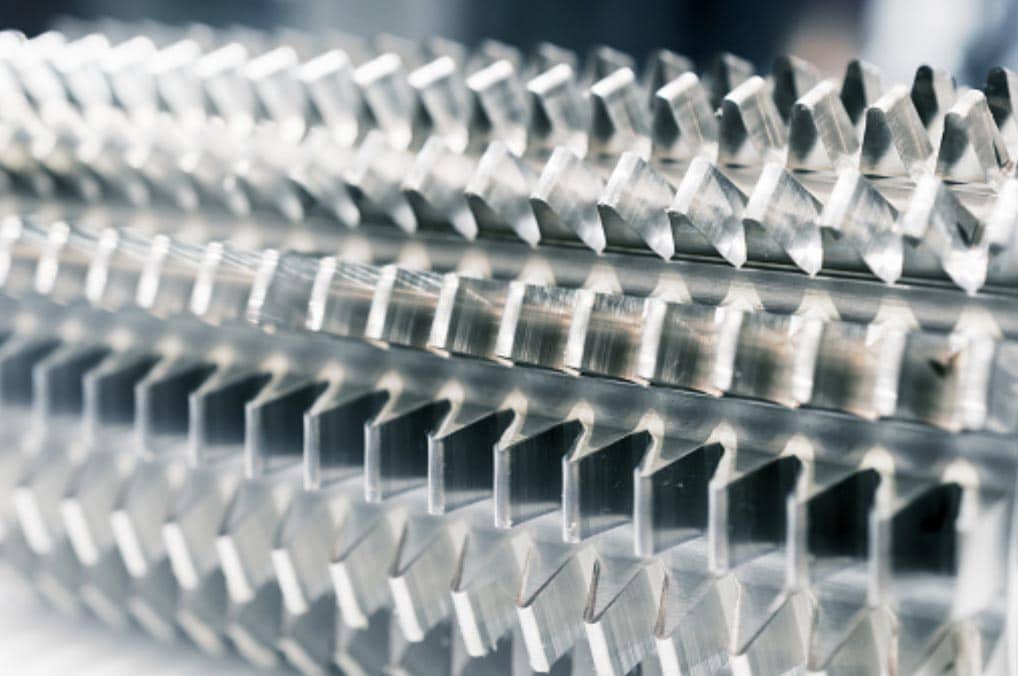

Industry: Gear hobbing machine

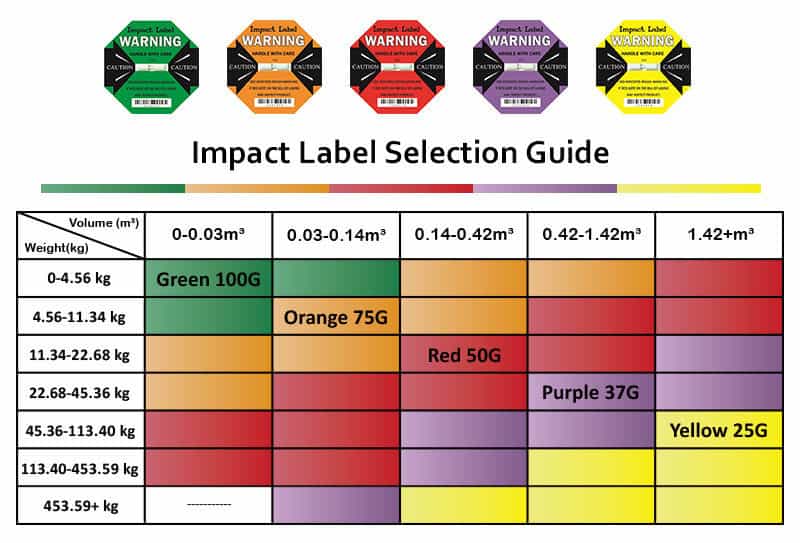

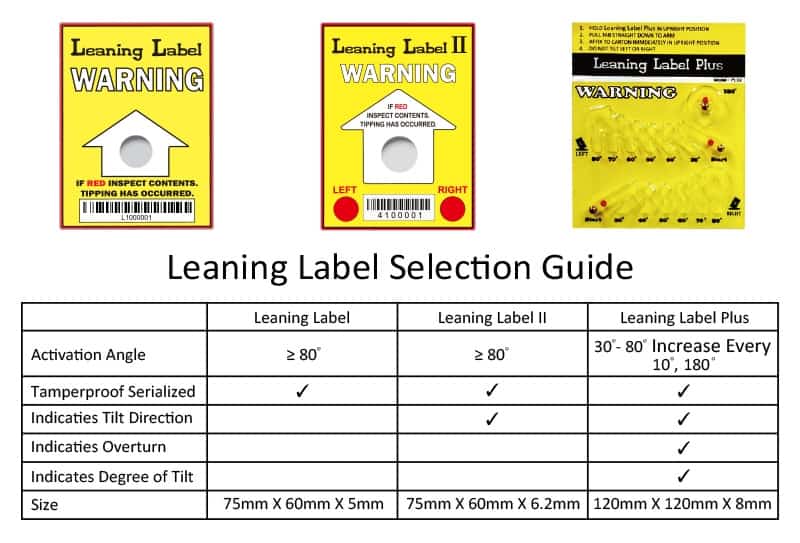

Solution from Wan-Yo: shock indicator

What is a hobbing machine?

A hobbing machine is used in a wide range of industries, such as machinery industry, automotive industry, aerospace industry, energy industry, medical industry, and so on and so forth. Hobbing machines come in plenty of sizes to cut sprockets, gears, and splined parts, so they could help produce anything from tiny instrument gears. Our latest models of gear hobbing machines feature high precision and efficiency able to produce high-precision gears required in those important industries.

Why does shipping damage happen to the gear hobbing machine?

As we’ve known, each gear hobbing machine comprises tailstock, spindle nose, work table and motors which are the most sophisticated precision equipment. Thus, when the machines are handled without caution during transit, especially loading and unloading the items, shipping damage would happen and cause serious consequences. The hobbing machine could be broken or malfunctioned, and thus impact the products of those industries if we are not aware of the damage, which could result in compensation for their product damages and losses. Every time they file a damage claim, we will need a thorough examination after our clients return it, or even repair the machine, incurring additional costs.

What could we do to avoid shipping damage during transportation?

As mentioned earlier, shipping damage happens during transportation for tons of reasons, so protecting our gear hobbing machines becomes the number one priority and our single-minded goal. We turned to Wan-yo for the best solution. As a leader in shipping damage prevention, Wan-yo offered us some free to try their products before we officially cooperate.

What is a shock indicator?

A shock indicator is a kind of impact indicator for detecting and indicating a magnitude of shock during transportation. This device could alert us in real time to possible mishandling and delivery damage during transit. Besides, a shock indicator could be an effective reminder for handlers to take better care of the shipments since they are aware of being monitored when handling the cargo with shock indicators. Once the shock indicator is activated, showing an impact occurs, they can not be tampered, and handlers should be liable for the damage and loss coming behind that. Also, a shock sticker is pretty low-priced, so we could affix it on every item to protect all of our machines and parts.

In light of the risks during transit, we highly recommend that you start using shock indicators to protect all the shipments. Since prevention is better than cure, you may try your best to avoid shipping damage happening to your products. Contact Wan-yo for more details and free samples.