For companies, warehouse safety has always been greatly important. The accidents by forklifts are the most frequent. Improper using a forklift causes cargo damage and even casualties, it makes direct and indirect costs for the company.

|

Direct Cost |

Indirect Cost |

|

Worker Injuries: According to the U.S. OSHA investigation from 2011 to 2021, forklift-related incidents resulted in 900 death and an average of 7000 injuries annually. The most common incident cause is operator error and improper use. |

Staff Morale: Workplace accidents lower morale among employees. At the same time, low morale is a contributor to workplace accidents. These two feed off each other and can create an ongoing cycle that hinders productivity.

|

|

Violations: If the company violates the relevant regulations of the forklift, it will be punished with a high fine. Take the U.S. OSHA as an example, the fine of the companies that unsafe forklift use can cost as much as US$136,532. |

Insurance: Insurers consider both incident and OSHA violation history when establishing premiums. A company that is shown to have a history of such violations will pay markedly higher premiums than one that’s violation-free. |

|

Damaged Products: Improper using a pallet jack or stacker causes direct or indirect damage to the product. 1. Stabbed or rolled 2. Falling while moving the pallet 3. Collide the goods even though you’re not on purpose. |

Damaged Reputation: No company can guarantee that the products delivered to customers are 100% intact, but if it is due to ongoing human factors in the warehouse or transportation, it will seriously damage the corporate reputation. |

Forklift Safety Precautions

Loading

When using a hydraulic stacker or pallet jack, the fork into the pallet must be aligned with the fork groove at the bottom of the pallet. Confirm the upper and lower sides of the pallet have a distance with the fork and then plug it in slowly.

Driving

1. The speed limit for electric forklifts is 10 km/hr.

2.When turning or going uphill, always pay attention to the situation ahead and slow down.

Unloading

After the forklift is stopped, use the hydraulic lifting platform to put it down slowly, make sure it’s horizontally and vertically, and then slowly pull out after confirmation that the forks are not in contact with the upper and lower surfaces of the pallet.

Operating Regulations

1. Entering the warehouse must wear safety helmets.

2. You must slow down when passing the cross street or turning, and increase the height of the fork when going up and down.

3. When entering the passage, you must first check if there is any car passing by and must be no one around before entering the passage slowly.

4. Do not use non-standard pallets or wooden boxes.

5. Do not touch the pallet or tray when the fork is inserted or retracted.

6. After placing the goods on the shelf, the forklift must be moved straight back. Do not put the pallet down while moving back.

7. In the passage, when forklifts meet each other, they must warn each other (the empty forklift must stop, the forklift with goods on should be given priority to pass by).

8. Don’t put too heavy goods on the top shelf. The heavy goods should be on the bottom shelf, and the light ones should be on the top shelf.

9. Avoid overloading: The weight of each layer of goods stored must not exceed the maximum carrying capacity of the shelf design.

10. Prevent collision: Whether it is an electric or manual hydraulic lifting trolley, it should be handled gently to prevent collision with the shelf during the lifting operation.

11. When there are goods placed on the shelf, the operator is not allowed to enter the bottom of the shelf.

12. If you find that the goods on the shelves are tilted or the goods are not stacked neatly, immediately restock the goods and put them back in the right place.

13. If you find any serious damage to the beams and columns of the shelves, do not put anything on it, report to the person in charge immediately.

Summary

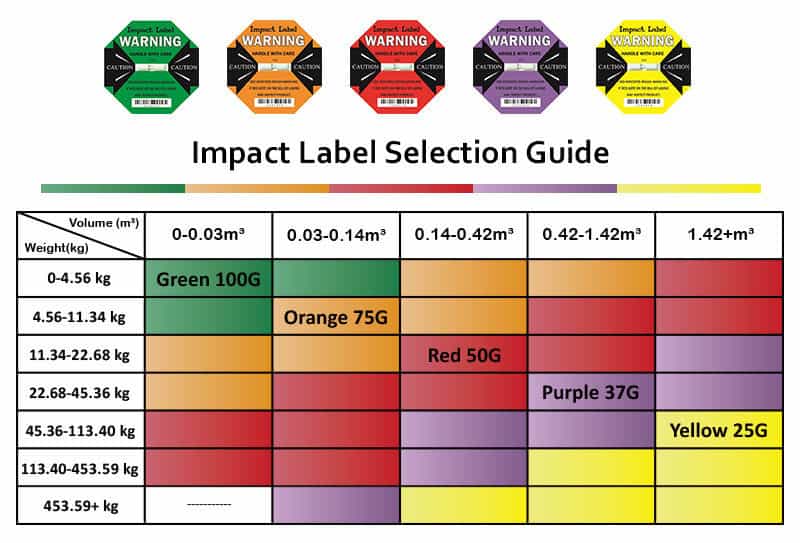

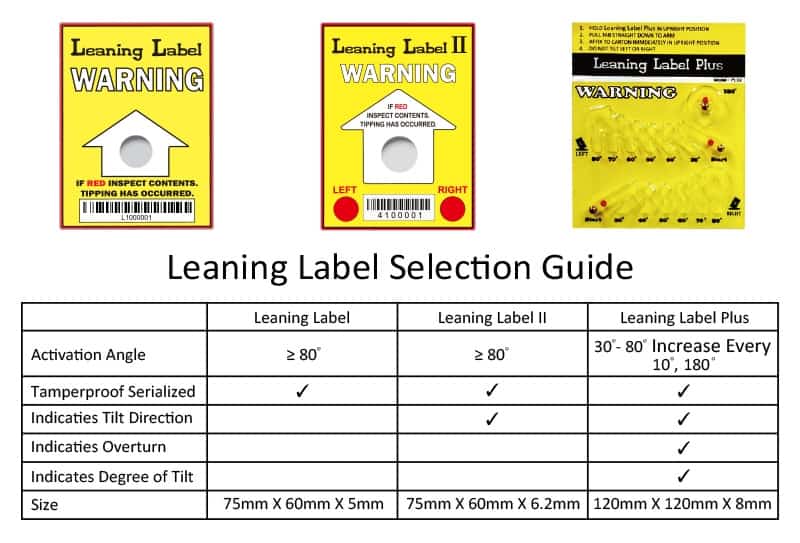

The improper use of forklifts in warehouses has always been troublesome for enterprises. Operators cannot always be full of energy and keep their attention, so monitoring is very important. If the “cargo monitor” can be applied to the cargo or pallets, it can be judged whether the goods have been collided or tilted during the warehouse operation, so as to prevent the customers’ claim about the damaged goods and bad reputation.

|

|

Would you like to prevent damaged product problems encountered in the warehouse, please don’t hesitate to contact us immediately by clicking the button below, we provide free consulting and free samples!