- Smarter Tools for Smarter Packaging

- Shock & Tilt Indicators: Essential Tools in Industrial Packaging

- Integration without Disruption

- Data-Driven Packaging Validation and Supplier Control

- Reduce Shipping Damage Without Over-Engineering

- Real-World Success Stories

- Conclusion: The Future of Industrial Packaging is Intelligent

Smarter Tools for Smarter Packaging

In a world where global supply chains are longer and more complex than ever, packaging engineers are tasked with more than just protecting goods—they must optimize for cost, space, sustainability, and traceability. Traditional protective materials can only go so far. For true control over your packaging system, engineers are turning to impact and tilt indicators as a critical tool in modern industrial packaging solutions. These devices not only offer insight into handling conditions but enable data-driven decisions across design, shipping, and supplier accountability.

If you’re a packaging engineer looking for how to reduce shipping damage, streamline packaging validation, and justify your packaging decisions with data—this article is for you.

Shock & Tilt Indicators: Essential Tools in Industrial Packaging

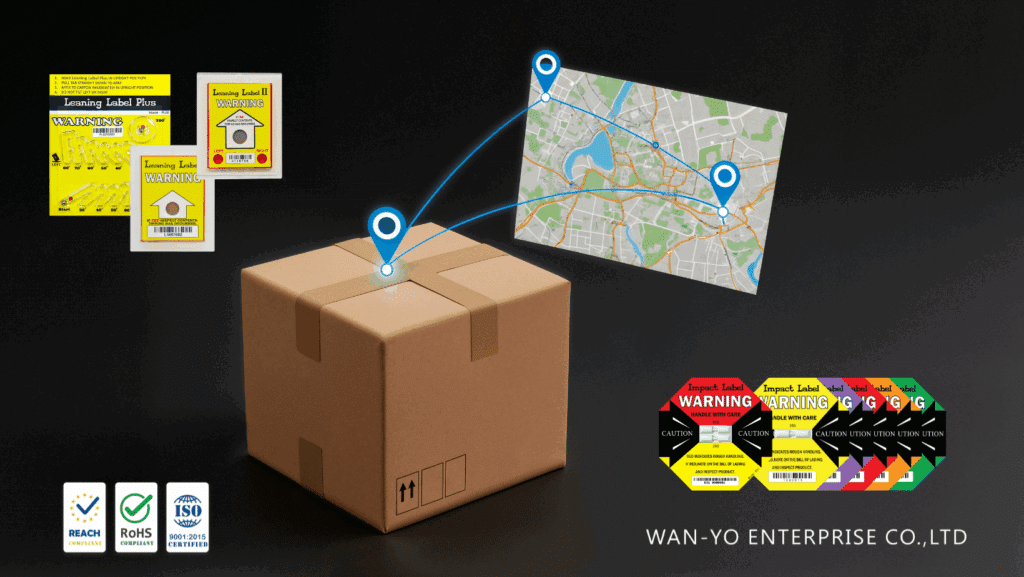

Shock indicators detect g-force thresholds exceeded during transit, while tilt indicators reveal if a package was mishandled, tipped, or stored incorrectly. Though simple in appearance, these shipping indicators serve as silent observers that capture key logistics events and inform whether your packaging optimization efforts are truly effective.

Why they matter:

-

Detect mishandling during shipping or warehousing

-

Act as visual deterrents to reduce careless handling

-

Provide objective data for packaging failure analysis

-

Validate packaging performance without invasive sensors

Packaging engineers use these tools to map shock sensitivity to protective design needs—essential when handling fragile, calibrated, or high-value components.

Integration without Disruption

One of the primary concerns engineers face is compatibility. The good news: integrating impact and tilt indicators requires no design overhaul. Whether your solution involves crates, pallets, cartons, or reusable containers, these devices are compact, adhesive-backed, and adaptable to nearly any industrial packaging solution.

You can specify:

-

Activation threshold (g-force sensitivity)

-

Tilt angle sensitivity

-

Mounting location (top load, side face, etc.)

These features make it easy to incorporate indicators into both prototype testing and full-scale production.

Data-Driven Packaging Validation and Supplier Control

What if you could know exactly when and where damage occurred—before a customer even opens the box? With indicators, that’s now standard.

For packaging engineers, the ability to monitor and log shipment conditions helps:

-

Perform packaging failure analysis when issues occur

-

Justify packaging material selection during audits

-

Collaborate with logistics teams for corrective training

-

Hold third-party handlers accountable in your supply chain control

In the event of repeated incidents, indicators can serve as a trigger to re-evaluate current packaging specs or introduce better dunnage, bracing, or cushioning.

Reduce Shipping Damage Without Over-Engineering

Overprotective packaging wastes material, increases weight, and drives up shipping costs. But without monitoring tools, reducing protection feels risky.

Shock and tilt indicators solve this dilemma. By tracking real-world conditions, packaging engineers can design smarter, lighter, and leaner packages that still achieve optimal protection. This supports ongoing packaging optimization and sustainability goals.

Companies using WAN-YO’s indicators have reported:

-

50-70% fewer product returns due to transit damage

-

Fewer warranty claims thanks to accurate monitoring

-

Streamlined design cycles with validated performance criteria

This isn’t guesswork—it’s packaging science backed by real shipping data.

Real-World Success Stories

Example 1: Medical Device Manufacturer

After a spike in returns, a global device OEM introduced shock indicators to evaluate if their packaging could withstand international air freight. The data showed repeated mishandling at a specific transfer hub. With this insight, they reinforced corner protection and resolved the issue—without increasing foam content across all shipments.

Example 2: Precision Instruments Exporter

To meet stricter QA specs, an exporter of high-precision tools used tilt indicators to validate that boxes remained upright through final-mile delivery. This helped them pass stringent packaging validation for a new European distributor.

Conclusion: The Future of Industrial Packaging is Intelligent

For packaging engineers, the pressure to deliver performance and efficiency simultaneously is growing. You can’t afford to guess. By integrating impact and tilt indicators into your workflow, you gain data, control, and confidence in your packaging strategy.

Whether you’re designing for aerospace, electronics, industrial components, or sensitive instruments, smart indicators unlock a higher level of industrial packaging solution—one that’s measurable, testable, and reliable.

Ready to Engineer Out Damage?

Join the thousands of engineers using WAN-YO shock and tilt indicators to optimize designs and reduce shipping damage.

📩 Request a sample kit or consult with our technical experts today

| Free Consultant & Free Trial |

| Impact Label |