When an employee starts a job in the retail sector, they are taught is where to put damaged products. This means that the damaged product is very common to see. In manufacturing, the annual cost of damage to each pallet or skid product is about USD $3.5, and the damage caused during the transportation is about USD $0.5. Day after day, there will be huge losses in the supply chain.

Effective ways to reduce product losses in the supply chain should be the first priority of every business. Data collection in logistics and improvement in package technique make as much as possible to reduce product losses.

Product Loss Happened in Supply Chain, Why?

The causes of damaged products in a supply chain always happen. However, they fall into the following categories:

● Improper Package: Many products are packed into cartons improperly or a failure to correctly stack those cartons on a pallet.

● Mechanical Failure: Supply chain automation isn’t always able to sense when something goes wrong and may damage lots of products.

● Human Factors: The probability of human factors is actually very high to cause damage, no matter in the process of loading and unloading goods or moving goods.

● Improper Storage: Wrong storage environment may cause damage to the products, such as temperature, humidity, and sunlight.

Prevent shipping damage and save unnecessary expenses increase the profit for your company.

5 Technique to Reduce Product Losses in the Supply Chain

1. Redesign Packaging

Redesign the product packaging to better protect the product according to the damage to the existing product, such as rearranging bubble warps or packaging foams.

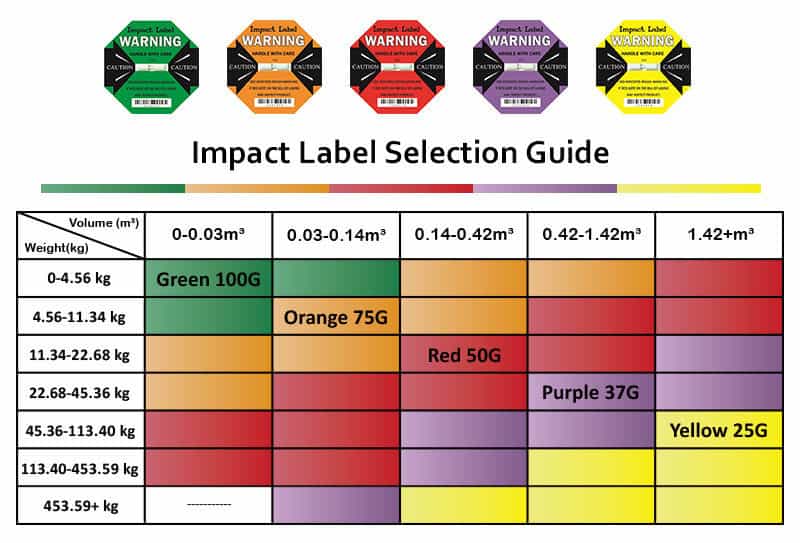

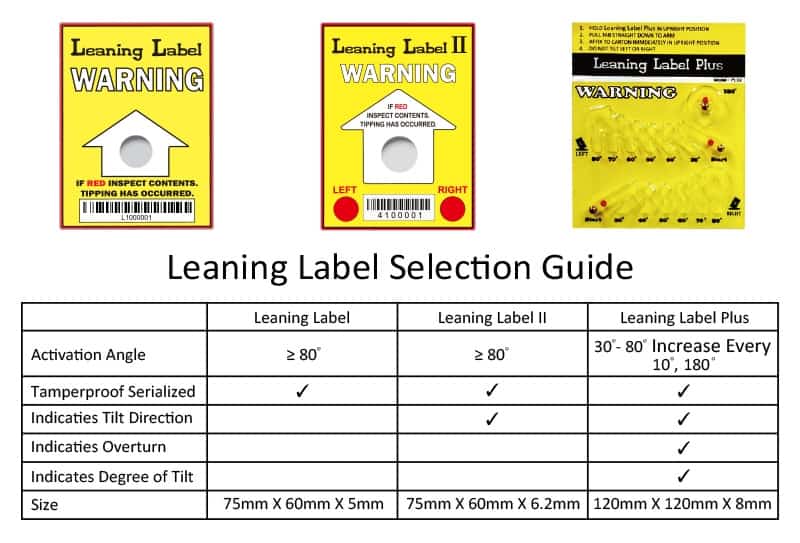

2. Use Impact Label / Leaning Label to Monitor Goods

Using the logistics monitor Impact Label and Leaning Label to monitor the supply chain will effectively reduce the damage rate of goods by more than 70%; according to the American Packaging Association, a piece of goods from the beginning to the final use, there are 4–6 chances of falling from a height of more than 80 cm. Among them, 6% of the goods may be damaged.

3. Tracking Cargo

You can grasp information more quickly through GPS and Good Tracking System. For example, goods are stored in the wrong place or the route is incorrect, which may cause damage to the goods.

4. SOP for Supply Chain Management & Record

Another way to reduce product loss in the supply chain is to establish a standard operating procedure (S.O.P). For instance, the procedure for storing cold chain items should ensure not only in the proper location but also correct maintained temperature. The most important thing is to consider the required processes in the supply chain management plan and ensure that records are kept.

5. Environmental Sanitation

Keeping loading docks, warehouses, and transportation vehicles clean and dry. This means that any causes of injury or incidence, such as discarded cardboard, plastic wrap, and tape, need to be swept up and properly disposed of. Otherwise accidents may be accidentally caused.

How Can We Help You to Reduce Product Damage in Your Supply Chain?

Effective Packaging Solution requires extensive data collection, careful analysis, and creativity in developing solutions. Reduce product damage needs time.

Now, you only need to contact us through the button below, and you will be able to get the packaging solution that fits your products for FREE.