Impact Tube Shock Sensor

IMPACT TUBE | Tiny shock impact indicators with tremendous effects watch the whole journey

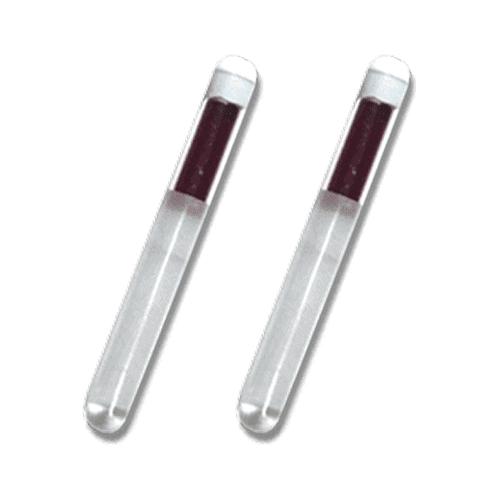

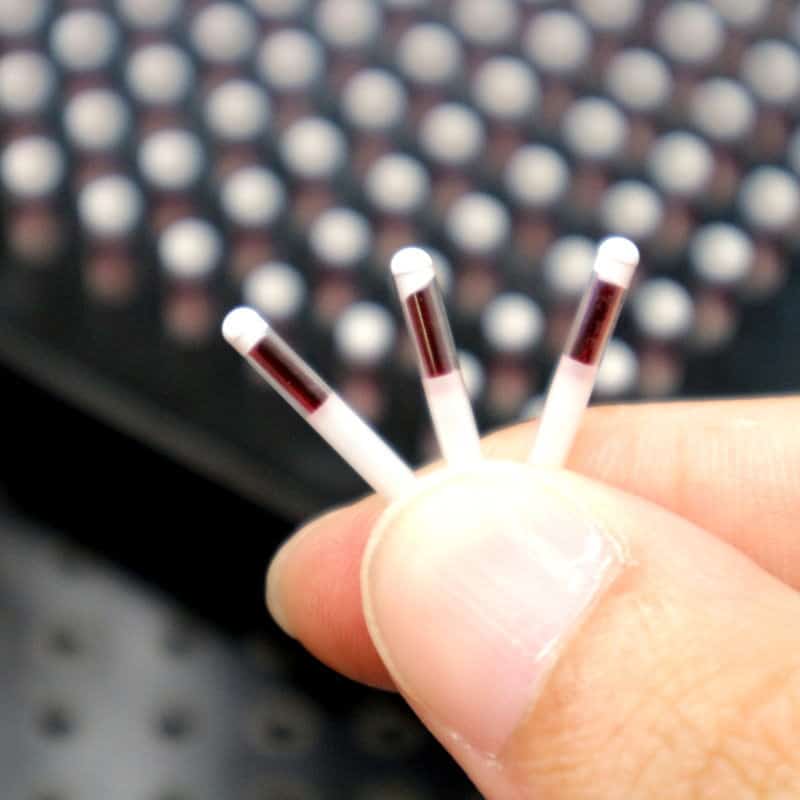

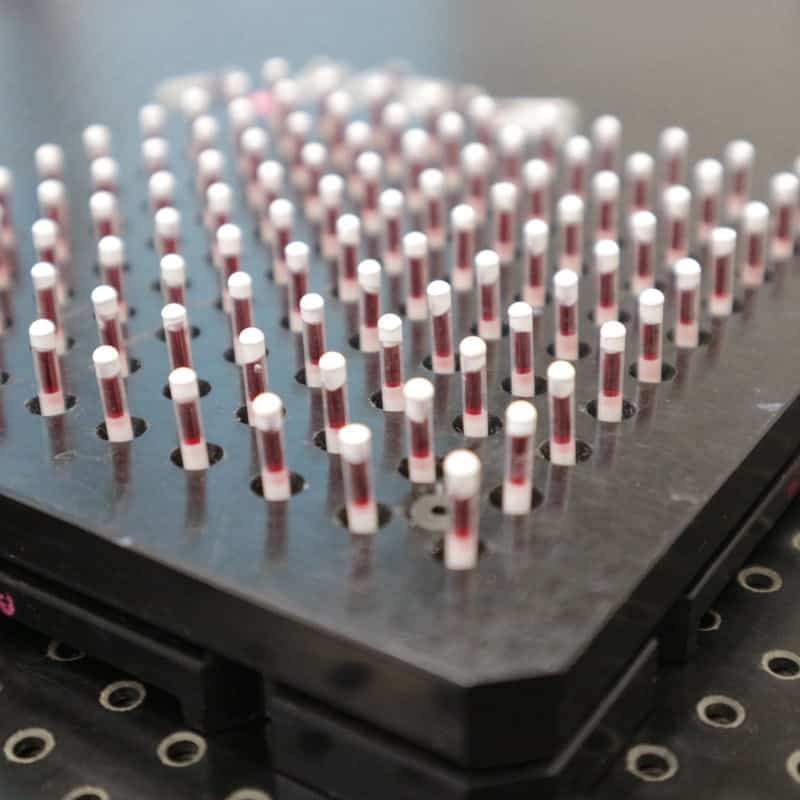

Tube-shaped impact indicators can be mounted or embedded seamlessly into products where space is limited to monitor excessive impacts and understand the conditions experienced by the product even when it is outside protective packaging.

【PRODUCT FEATURE】

- The Tiniest Proactive Impact Indicator

Compliance and field-tested for use in various manufacturing, processing, shipping, and usage environments. Convenient to integrate and incorporate into your products. - Visual and Irreversible White to Red Color Change

Tamper-proof design prevents concealment of activation in the absence of obvious interference. Accurate impact force for analysis - Cost-Effective Quality Control Diagnose Tool & Accountability

Avert potential problems such as misalignment, calibration loss, or warranty-related repairs often resulting from improper handling. - Simple To Use

A mechanical device requires no electric power without worrying about additional power consumption. Pinpoint product damage, indisputable evidence of mishandling of rental merchandise, and warranty repair issues - ISO 9001:2015 Certification & OEM Service

Product page – 6 tabs

-

Description

-

Specification

-

Instruction

-

Application

-

Document

-

Download

Shock Tube impact indicators are designed to integrate into limited hardware to detect excessive impacts. Red indicates an excessive impact force experienced on your products. Impact Tube is the smallest, mechanical-operated shock impact indicator, providing reliable shock detection at minimal size and weight for MFGs to embed this impact-sensing technology directly into products or/and integrate it into your system hardware without requiring a power source. Impact Tube is an ideal solution to power and cost considerations when you need to know if product mishandling may have resulted in misalignment, attribution of liability, loss of product calibration, or warranty-related repair issues. If you meet the following conditions, Impact Tube should be your first choice. Tubes are selected based on the impact amplitude and duration, which define a product’s damage profile. Lower g amplitudes with longer durations are more likely to damage heavier products, whereas higher g amplitudes with shorter durations are more likely to harm lighter products. There are 7 G-value sensitivities available for choice. Heavier = More likely to be damaged by lower g amplitudes with longer durations. Lighter = More susceptible to higher g amplitudes with shorter durations. Looking for Shock Tube Impact Sensor Indicators? We recommend you contact us to discuss your application so that our team can assist you in choosing the correct Impact Tube for you or if you wish to purchase a large number. Impact Tube Shock Sensor Impact Indicator

When to use?

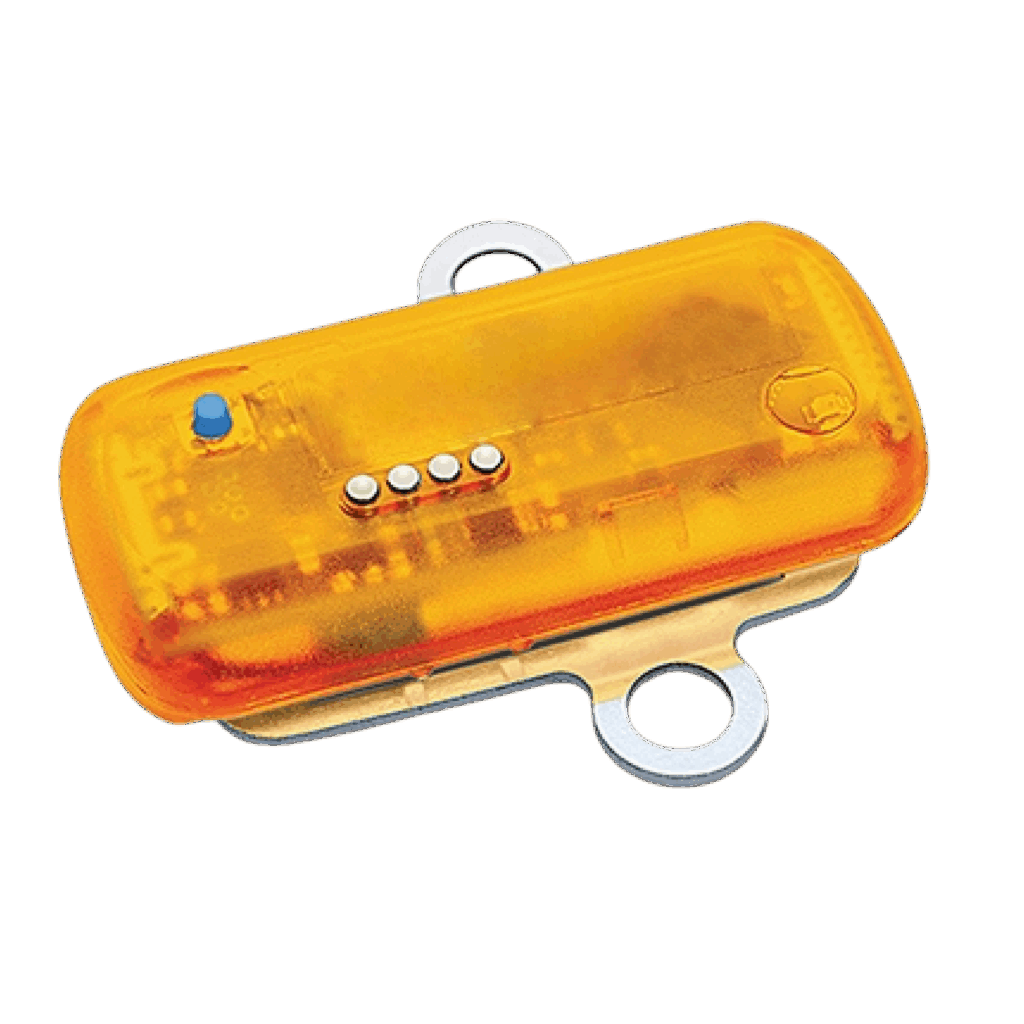

CLIP LABEL W/ IMPACT TUBE(s)

SPECIALITY CONSULT

Specification

50G/75G/100G : Φ 2.4 x 19 mm

Indicator Placement (Please reload the page if the display is blank.)How to use Impact Tube?

Simply glue or fix the Impact Tube inside the product.

Patent

SGS report

Our Recommendation

Besides shock indicator, we have tilt indicator, pallet cushion to give you a hand. Check what we can do for you!

Related Products

Contact

Feel free to let us know if you have any questions.