Dual Impact Label 【’2X’ G Force Indicator】

PRODUCT FEATURE

- VISUAL DETERRENT & ALERT HANDLERS

Shock Monitor & 2 Impact Point Detection Accurately Diagnose Whether Protective Packaging Was Enough To Absorb the Damage Shock. - MONEY-SAVING, TIME-SAVING, EFFORT-SAVING

Decrease Direct/Indirect Cost of Transportation-Caused Damage. Quick Inspection Before Acceptance. Increase Integrity of Product and Enhance Corporate Image. - SIMPLE TO USE & SIMPLE TO ANALYZE

No Electric Power Required, Only Peel and Stick. Accurate Impact Force Helps Analyze Effect of Packaging Protection - LOGISTICS & HANDLING MONITOR

Pinpoint Trouble Spots In Supply Chain, Indisputable Evidence of Mishandling for Freight Claims, or Repeated Mishandling - TAMPER PROOF & LOGISTICS ACCOUNTABILITY

Unique Serial Number to Verify Authenticity, Manage Product Conveniently, and Clarify Responsibility For Damage - ISO 9001:2015 CERTIFICATION & OEM SERVICE

Certified International Quality Assurance Control

Product page – 6 tabs

-

Description

-

Specification

-

Instruction

-

Application

-

Document

-

Download

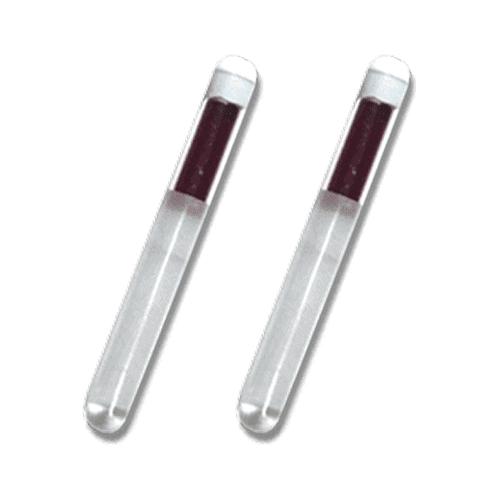

Dual Impact Label, double G Force Indicator labels by WAN-YO can detect two different impact set G-force which is an upgraded and brand new version of the traditional shock indicator label with double tube impact sensors. Activation View The double tube G Force Indicator provides more accurate shock detection and monitors your goods during transit or in storage, as well as can help to “reject cargo” or “defective pre-warning” which makes work time-effective for corporates. General G Force Indicators have only one display window and usually fail to reflect the accurate impact force. The impact force is much larger than the selected impact detector label, resulting in the products getting more severely damaged. Double G Force Indicator is also an impact diagnostic tool to be used to determine package sensitivity during drop testing for packaging engineers, distribution analysts, product designers, and manufacturing engineers. The Dual Impact Label is widely used for the following situation. 1. Shorten inspection time before acceptance 2. Analyze cargo damage from warehouse, distribution to destination 3. Confirm package sensitivity during transit Select the first model that complies with your package and then confirm to add a higher/lower sensitivity model. When the higher sensitivity model activates, the cargo can be rejected directly because impact force is greater against impact resistance, probably damage has happened. When the lower sensitivity model activates, the product is probably defective because of a slight collision during the delivery process. The consignee should conduct a closer examination before acceptance. No Idea of Selecting a Suitable Dual Impact Label G Force Indicator? We recommend you contact us to discuss your application so that we can assist you in choosing the correct types for you or if you wish to purchase over 2000. Dual Impact Label Double G Force Indicator

WAN-YO Dual Impact Label – G Force IndicatorHow Do G Force Indicators Help?

When to Use?

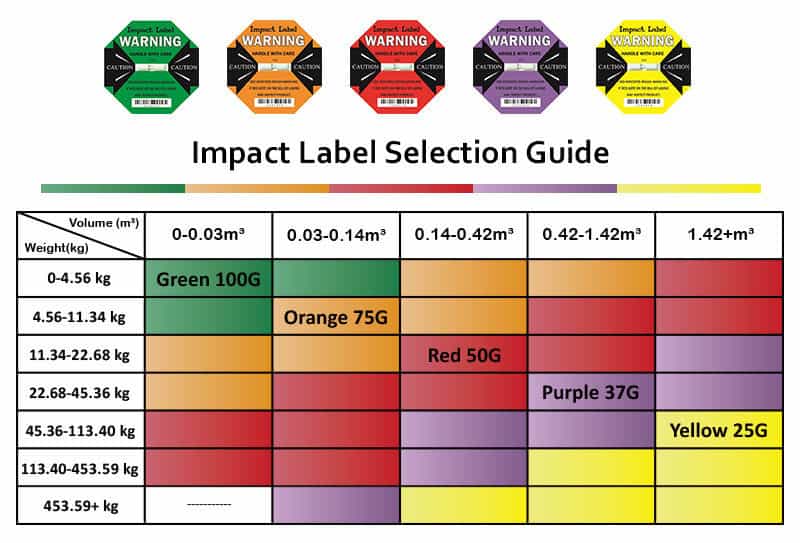

Selection Guide

.Reject Shipment

.Pre-Warning

4 WAYS TO SELECT

SPECIALITY CONSULT

Specification

Indicator Placement (Please reload the page if the display is blank.) Indicator Placement (Please reload the page if the display is blank.) ※ Suggestion: Stick 2 Dual Impact Labels on the Opposite Corners for Large Goods.How to use Dual Impact Label Doube G Force Indicator?

Patent

SGS report

Brochure

Our Recommendation

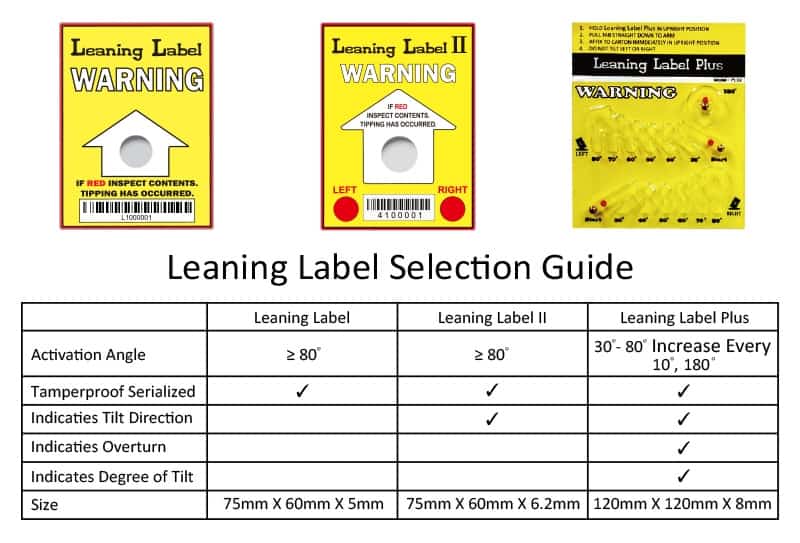

Besides shock indicator, we have tilt indicator, pallet cushion to give you a hand. Check what we can do for you!

Related Products

Contact

Feel free to let us know if you have any questions.