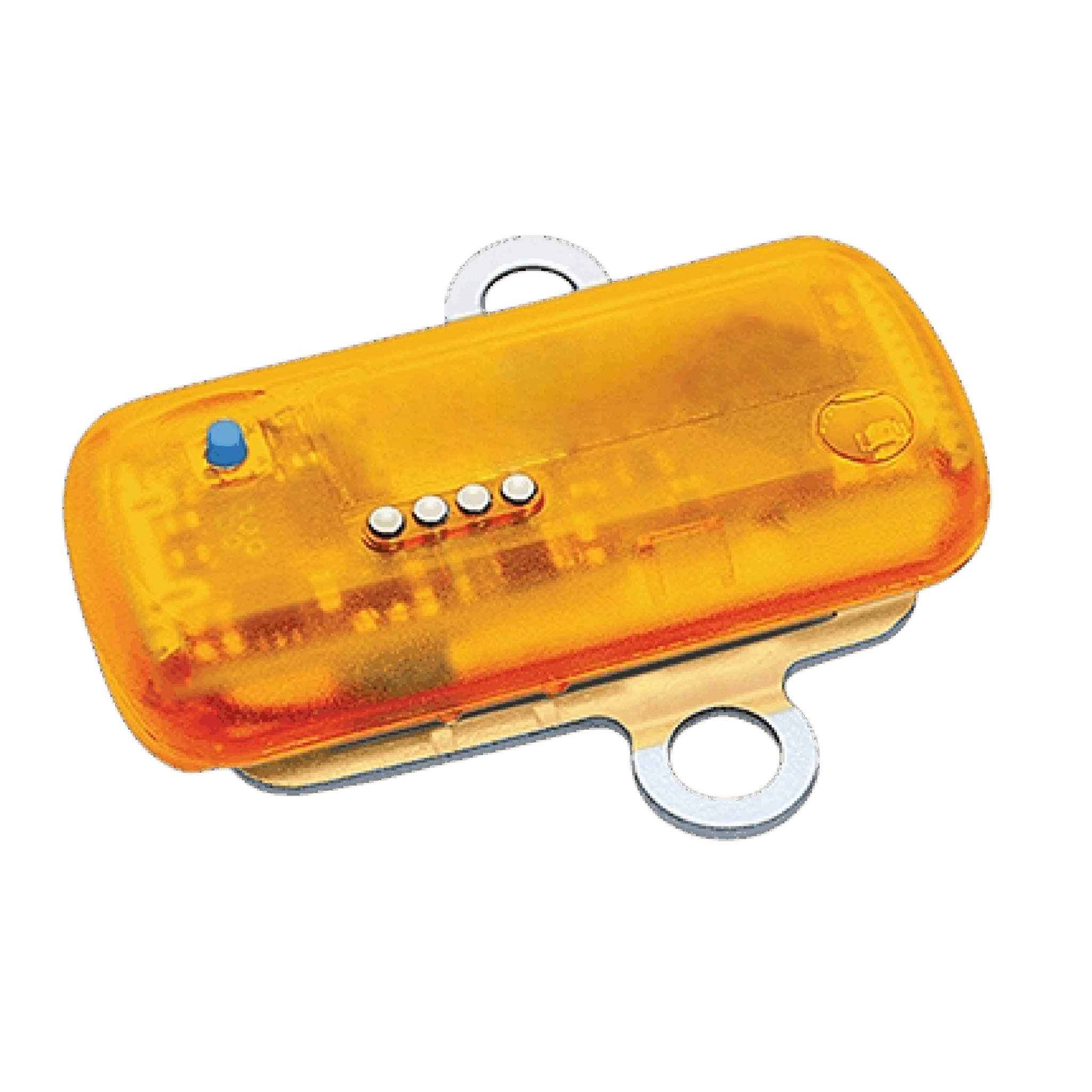

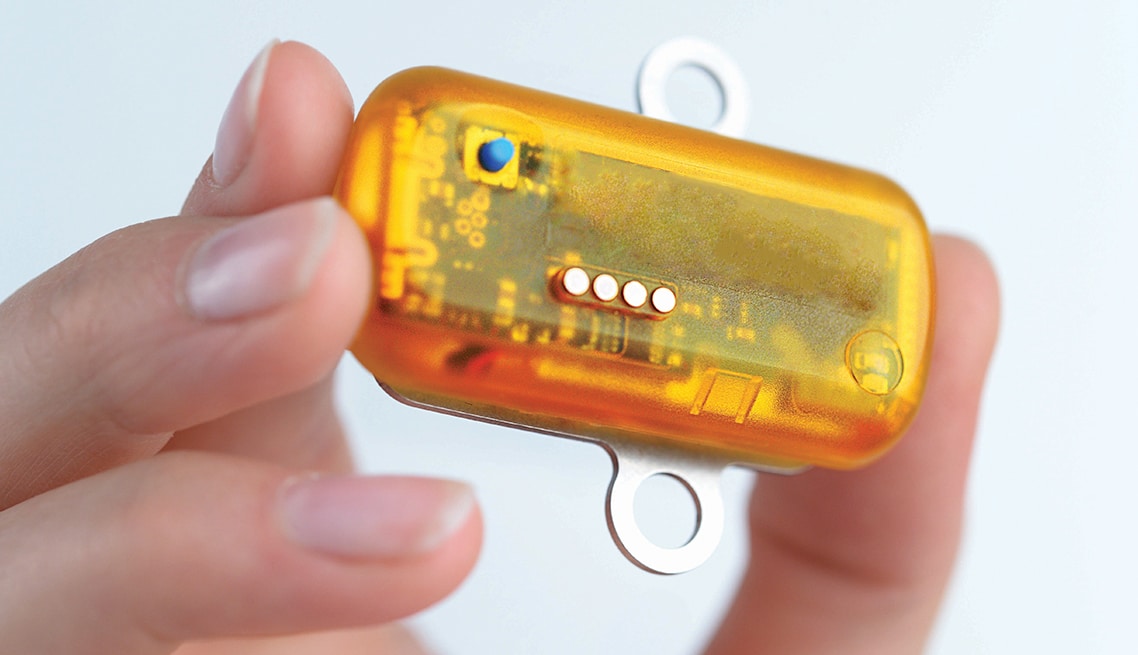

Shock Data Logger w/ Temperature Sensor

Accelerometer Impact Recorder | monitoring & recording critical events, impact/temperature

The Shock Data Logger has 2 acceleration sensors ±15 g and ±200 g and temperature sensor, designed for precise transport monitoring, effortlessly captures shocks. Its 3-axis sensor is ideal as an impact recorder for transformers, storing up to 2 million total readings.

【PRODUCT FEATURE】

- DUAL ACCELEROMETER SENSORS (±15G & ±200G)

- MASSIVE MEMORY CAPACITY (over 2 million data points)

- FREE ANALYSIS SOFTWARE INCLUDED

- VERSATILE POWER OPTIONS

Rechargeable 230 mAh lithium-polymer battery offering up to 8 weeks of operation or a long-life 7700 mAh Li-SOCI2 replaceable battery lasting up to 2 years - ISO 9001:2015 CERTIFICATION

Product page – 5 tabs

-

Description

-

Specification

-

Instruction

-

Application

-

Download

The Shock Data Logger stands out as a professional solution for monitoring and documenting physical stressors such as shocks, impacts, and temperature fluctuations across dynamic environments. Whether you are shipping delicate electronics, industrial machinery, or transformers, this highly sensitive impact recorder ensures every vital event is captured with precision. Unlike basic sensors, the Shock Data Logger integrates dual 3-axis acceleration sensors—one ±15 g and one ±200 g—enabling accurate recording of sudden impacts at up to 6400 measurements per second. With a massive storage capacity of over 2 million readings, it can reliably record thousands of shock events over extended transport durations. Available models also include an internal temperature sensor, delivering a complete environmental picture alongside mechanical monitoring. Setting up the logger is remarkably easy with intuitive software that includes a dashboard for configuration, a report generator for quick summaries, and a detailed shock viewer for in-depth analysis. Data can be conveniently downloaded via USB, and the system even allows for automated report creation to simplify claim documentation and internal quality checks. Shock data loggers are essential tools for ensuring the safety and integrity of valuable goods throughout the transportation and handling process. By continuously recording and storing data related to impact and acceleration, these devices provide clear, objective evidence of what happens to a shipment from origin to destination. A shock data logger acts like a silent observer, detecting and logging every jolt or drop that could compromise the internal components of sensitive items—such as electronics, precision instruments, and high-value industrial assets. For instance, an impact recorder for transformers can reveal whether a power transformer has experienced damaging mechanical shock during transit, even if no visible damage is present. This level of visibility is critical in preventing failure in the field. In short, shock data loggers do more than just record impacts; they build trust, enforce accountability, and drive smarter logistics decisions. A shock data logger should be used whenever goods are exposed to mechanical risks during storage, handling, or transportation. This applies especially to sensitive, fragile, or high-value items where even minor impacts can cause hidden damage. Industries that rely on precision, safety, and accountability—such as aerospace, energy, electronics, and healthcare—frequently deploy shock loggers as part of their risk mitigation strategy. Ultimately, a shock impact recorder isn’t just a device for data collection—it’s a critical safeguard that helps reduce financial loss, ensure operational continuity, and protect brand reputation. Looking for Shock Data Logger/Impact Recorder? We recommend you contact us to discuss your application so that our team can assist you or if you wish to purchase a large number. Read More 【Are Damaged Goods Impacting Your Service?】 It may not come as a surprise that most Exporter’s number one pain is damaged goods, even after paying top dollar to reduce damages. Shock Data Logger (Shock Impact Recorder, Shock Logger)

How Do Impact Recorders Help?

When to Use a Shock Logger

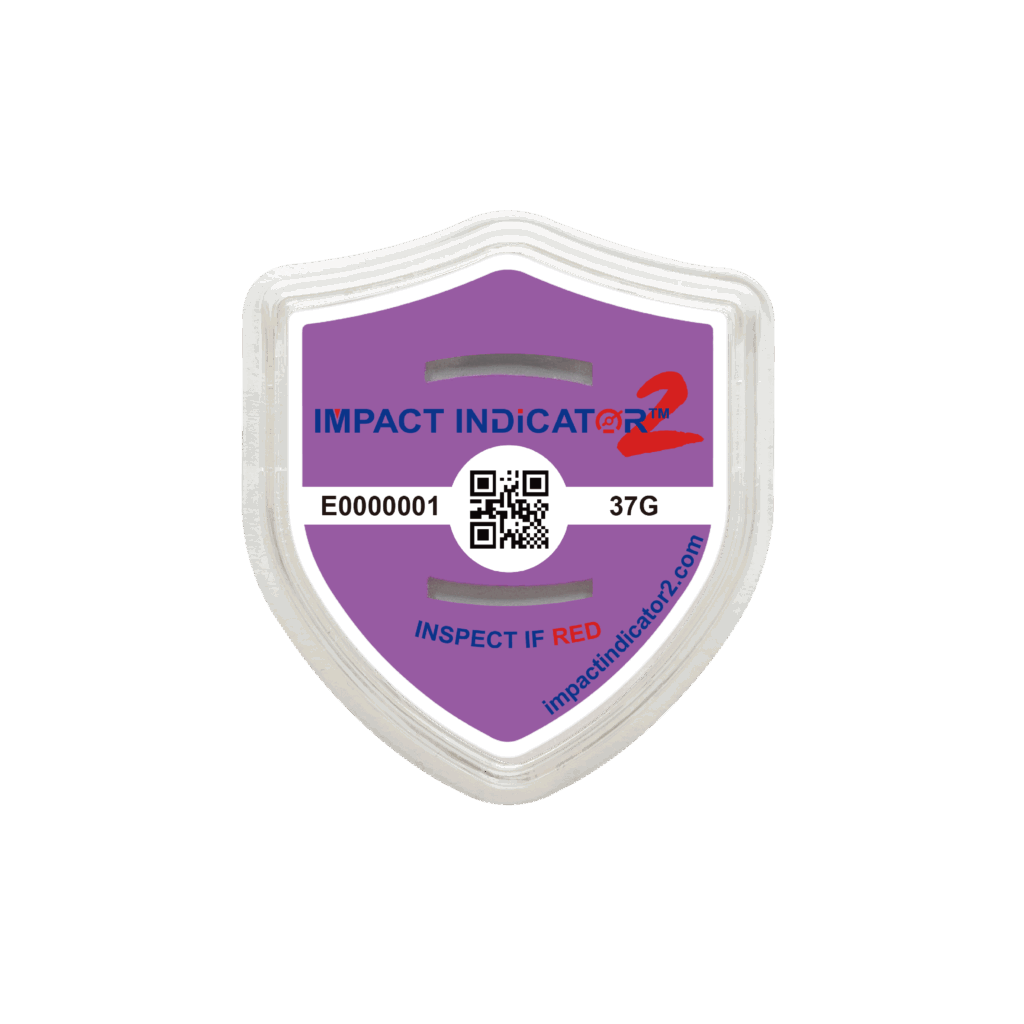

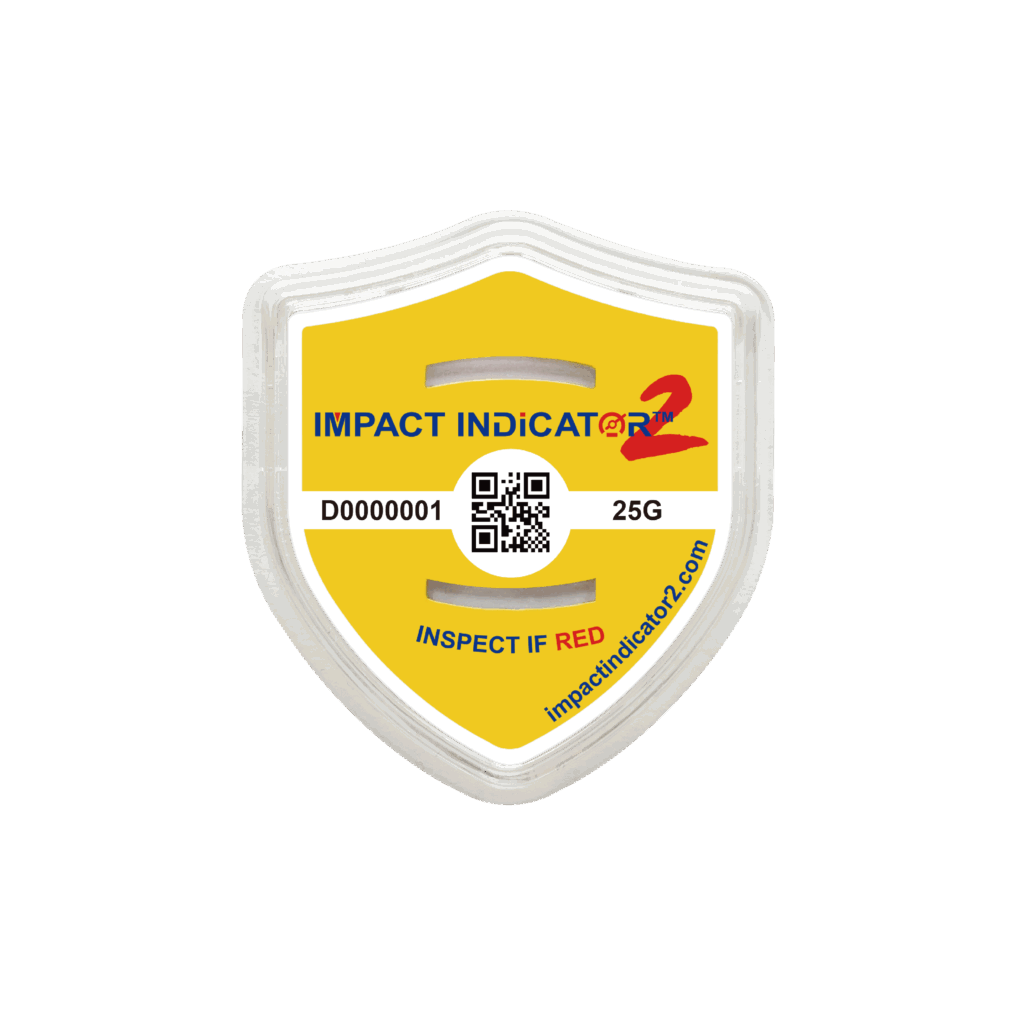

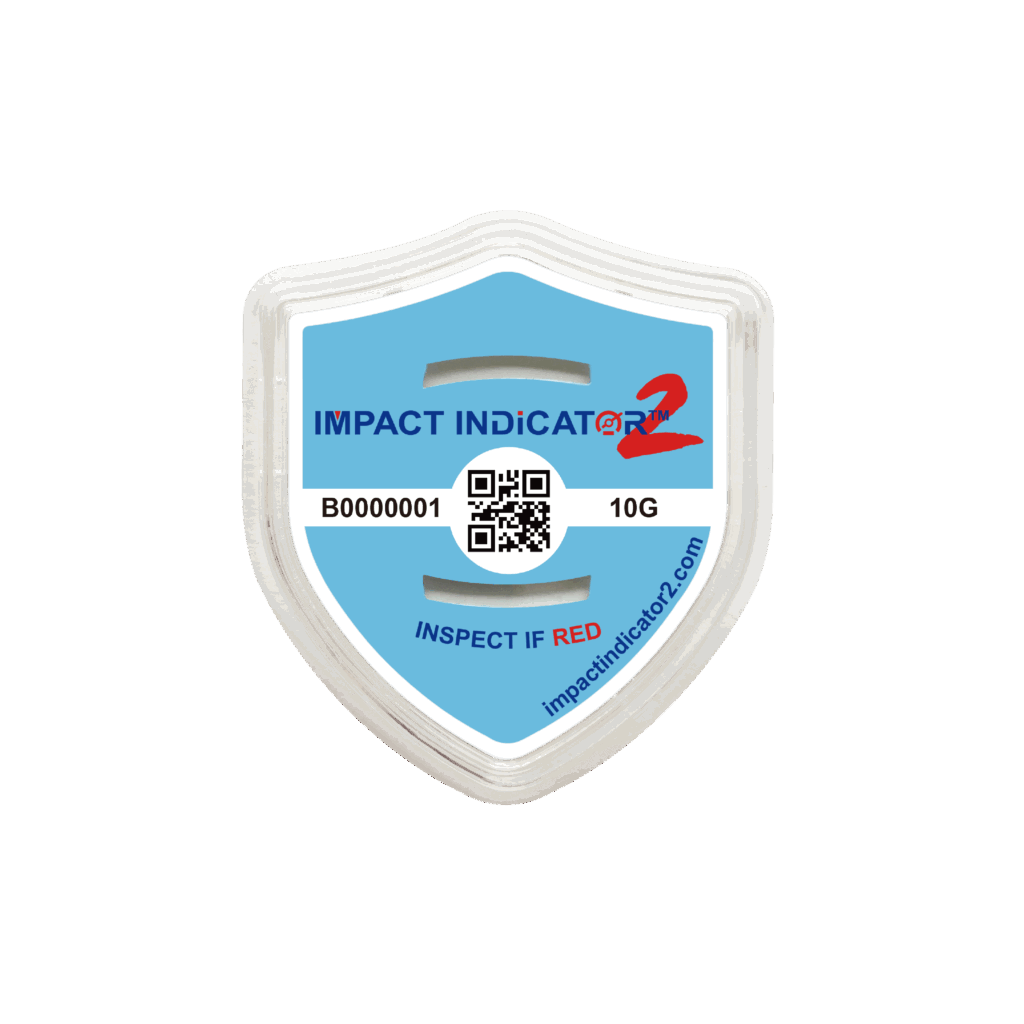

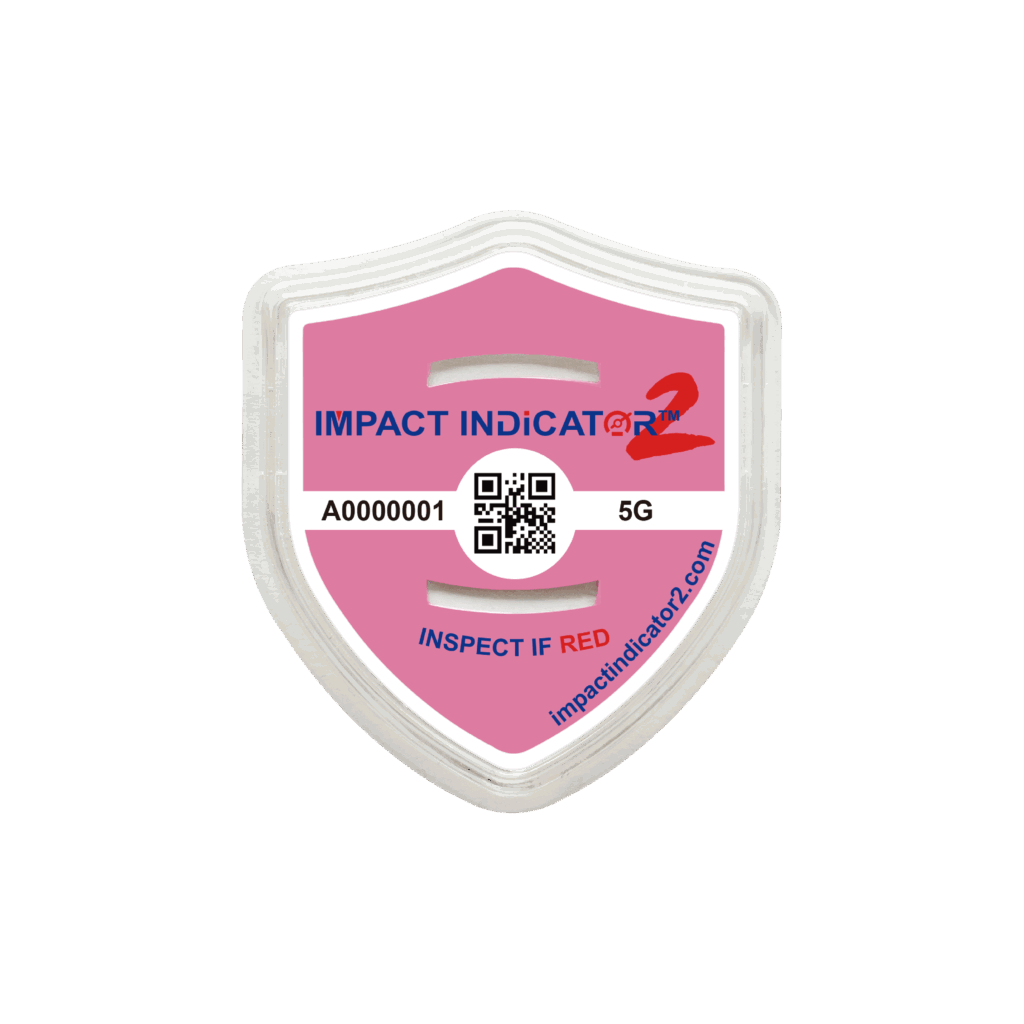

IMPACT INDICATOR SERIES

SPECIALITY CONSULT

Specification

Our Recommendation

Besides shock indicator, we have tilt indicator, pallet cushion to give you a hand. Check what we can do for you!

Related Products

Contact

Feel free to let us know if you have any questions.